Congratulations on your purchase of the Handle It Mobile Robotic Model 3000!

We designed the 3000 Series Mobile Stretch Wrap Machine to provide the ultimate in mobile stretch wrapping flexibility. It features:

- 250% powered pre-stretch for improved film economy

- User-friendly Siemens Simatic PLC touch screen control panel

- Fully customized wrap settings

- 94″ maximum load wrap height

- Daily workload – up to 350 cycles

- Acoustic warning at the cycle beginning and stop

- Battery charge monitoring and warning message on the display when the battery is low

- And many other features to improve and streamline packaging operations

Keep reading for a handy guide we put together to help you get started!

Operation

First, unplug the machine from the charging base and power it on by turning the power switch clockwise and holding it down for three seconds. If you need to reset the device, press and hold the black button for five seconds.

When you’re ready to get started, position the Model 3000 series so that the guide wheel is touching the pallet that you wish to wrap. You may adjust the height of the wheel up or down if necessary. Ensure that there is at least an additional 56” of clearance around the pallet for the machine to operate.

To start, press the white button to begin the wrap cycle. The machine will automatically play an acoustic sound as it begins to wrap the pallet. Once finished, it will play an acoustic sound to let the operator know the cycle is complete.

Charging

The Model 3000 Series is rated for performing up to 350 cycles per day. When the battery is low, the machine will display a warning message on the display screen. To recharge the battery, remove the hood from the body to expose the batteries and charger. Plug the machine into a 120VAC power source.

IMPORTANT NOTE: Damage to the batteries can occur if you charge the machine for less than 8 hours. To ensure battery life, do not attempt to run the machine on a low battery. Once the low battery alarm is displayed, immediately bring the machine back to the charging station.

Manual Mode

If you need to enter into manual mode, press the Menu button on the main screen. Then press “Manual Commands.” This will allow you to raise and lower the carriage by selecting the appropriate command and then pressing and holding the white button.

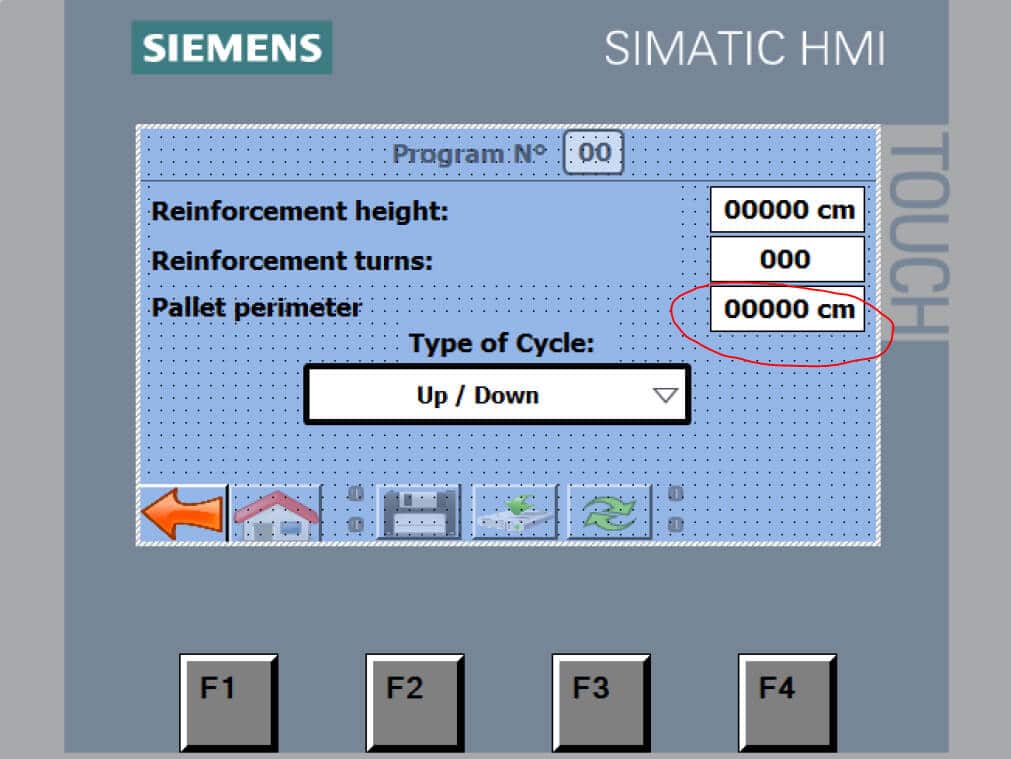

Editing a Cycle

To edit a cycle, go to the main screen and then press “Programs.” You will need to enter a password to continue. If this is your first time using the machine or the machine has been reset, you will need to enter in the default master password: 919

Refer to the machine manual for further information on passwords.

Once you’ve successfully entered the password, choose which program you would like to edit by pressing the box after the Program No. This will allow you to change the parameters of the program.

To save and execute your changes, press the Save, Load, and Refresh icons at the bottom of the screen.

- Only Up – Wrapped from bottom up

- Only Down – Wrapped from top down

- Up & Down – Wrapped upward and downward

- TSD – Machine pauses at top of pallet for top sheet application. Operator presses start once more to complete the cycle.

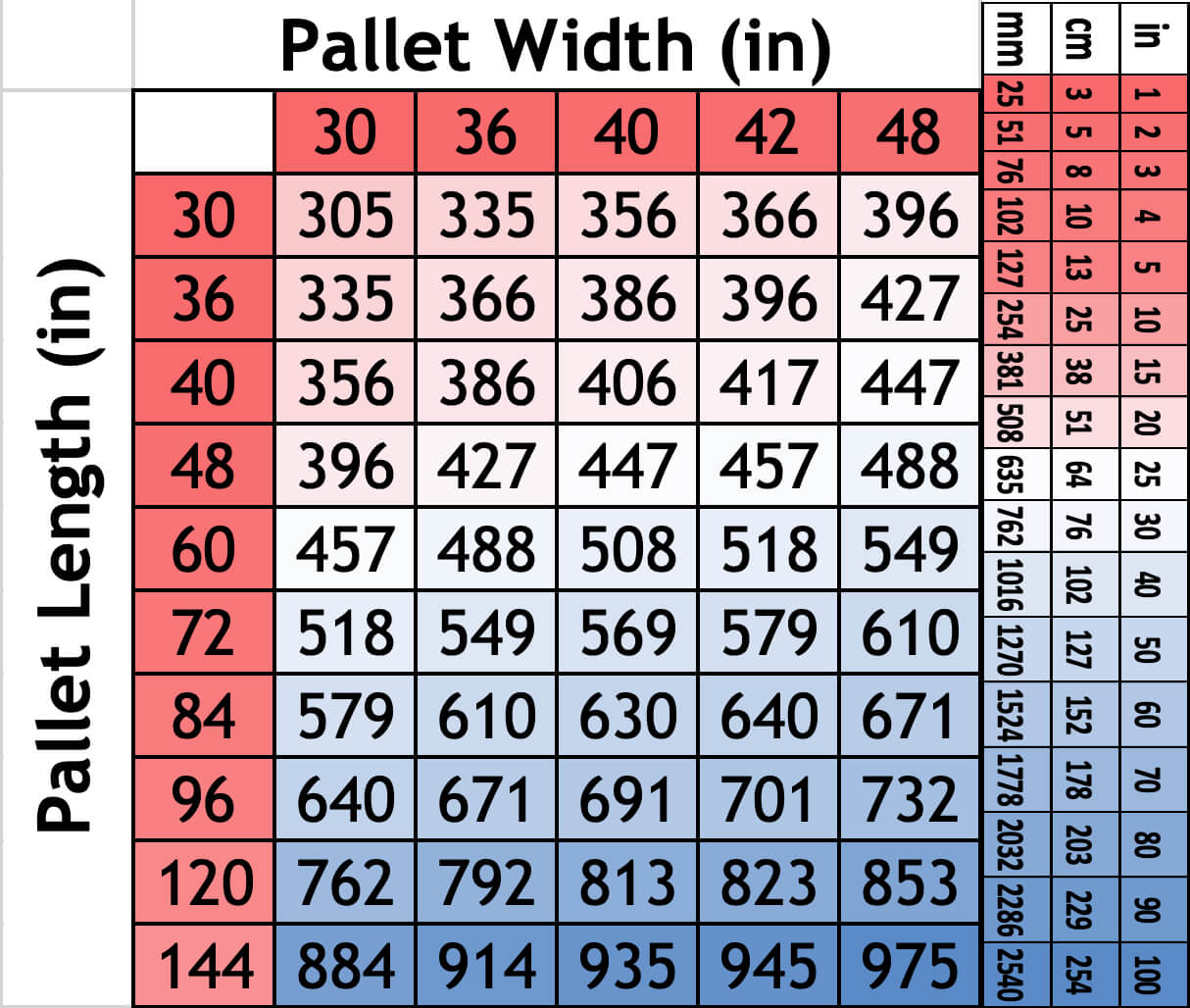

Pallet Perimiter Setting Conversion Chart

Find the cross-section of your pallet length and width and enter the number found in the pallet perimeter setting on your pallet/stretch wrapper.

Example: For a standard 48×40 pallet – enter 447 cm into the machine control panel during wrapping setup.

Optional Accessories and Stretch Wrap

Handle It offers many accessories, and shrink wrap options to help you get the most out of your new 3000 Series Mobile Pallet Wrapper.

To learn more, contact your local Handle It distributor for pricing and availability.