Stretch Wrapping Barrels, Drums, and Pails

Shrink wrapping machines from Handle It will allow you to safely, efficiently, and securely wrap pallets that contain barrels, drums, and pails. These items are often bulky and heavy—and can easily fall off a pallet and spill their contents if wrapped by hand.

Handle It pallet wrapping machines come with a wide range of useful features, such as:

- Storage of 18 to 32 end-user programs

- Rack and pinion carriage drive system for added reliability

- User-friendly control panel

- Ability to wrap up to wrap tall, unstable, or extremely heavy loads

- Up to 250% power pre-stretch (lower film costs by up to 60%)

- 118″ maximum load wrap height

- Wrap up to 300 loads per day

- Additional roping device provides extra wrapping strength at the bottom and top of the pallet

Recommended Products

850PS SEMI-AUTO STRETCH WRAP MACHINE

Top-of-the-line functions and a 250% power pre-stretch feature make the Model 850PS ideal for those who are looking for an affordable stretch wrapping machine that can wrap up to 100 pallets per day.

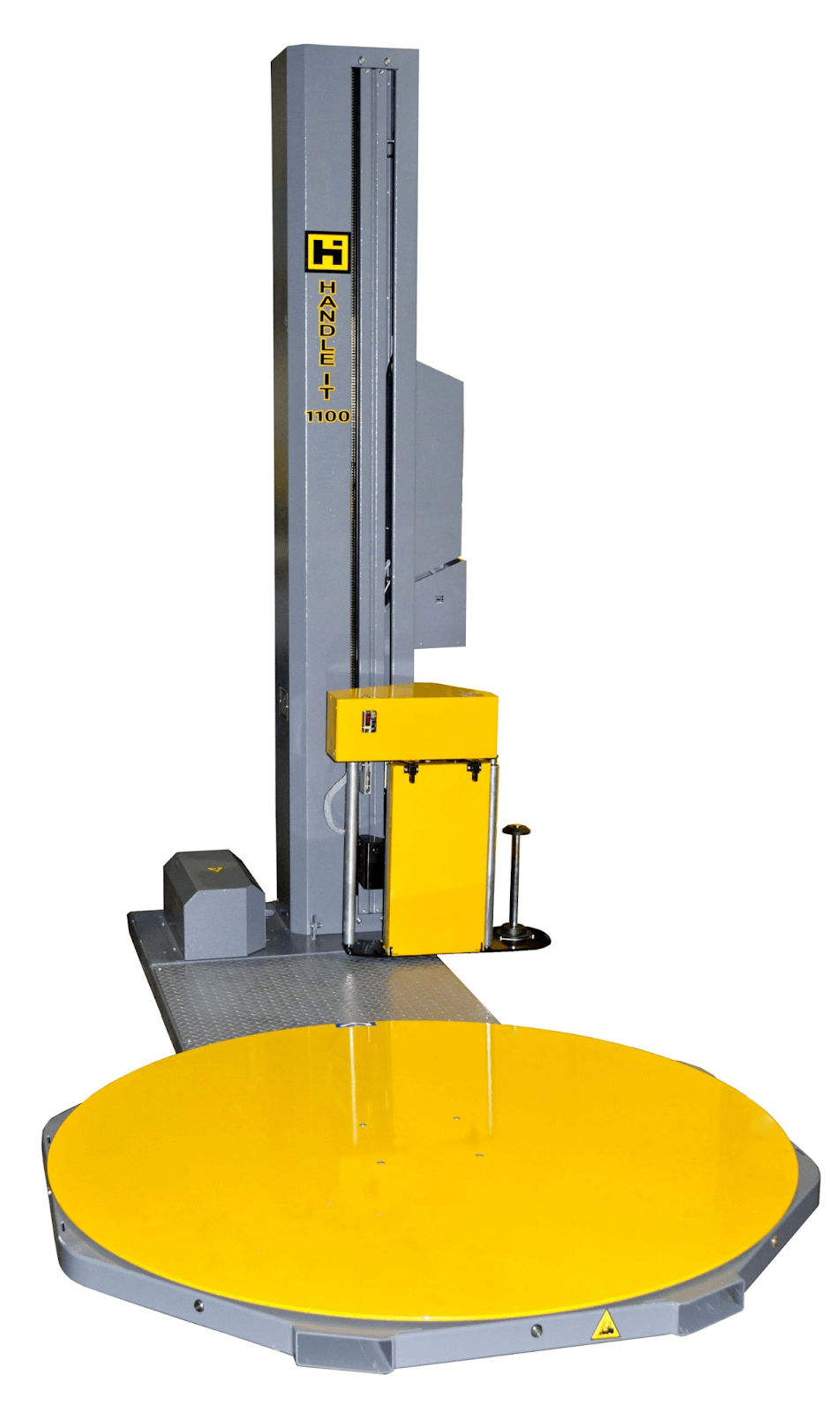

1100 SEMI-AUTO TURNTABLE STRETCH WRAP MACHINE

The Model 1100 semi-automatic stretch wrapper can wrap up to 300 pallets per day. It offers a wide range of features such as a 250% power pre-stretch and 94” max wrap heigh with an optional 118” extended height available.

1100AA-C AUTOMATIC STRETCH WRAP MACHINE

The Model 1100AA-C allows workers to perform the entire wrap cycle without leaving the forklift driver’s seat. Remote control comes standard along with 250% power pre-stretch, auto film attach, hot weld film seal, and auto film cut.

Pro Tips

Here are several Pro Tips that will help you securely wrap barrels, drums, and pails for transport:

- Start off with two to three top and bottom rotations with a 50% film tension for average loads.

- Try less tension and slower speeds on the initial setup. Gradually work your way up to optimize load containment and cycle time.

- Consider lowering film tension or using a thicker, more puncture-resistant film for wrapping products with sharp edges.

- Increase the top rotations and overwrap delay (“flanging” time), to ensure a high film band for outlier products at the top.

- For voids or empty spaces, try the fixed height setting or increase the flanging time (Model 1100)

- Lock in with set reinforcement, extra height and roping divide.

- Use variable tension to start with a lower tension at the pallet bottom. Gradually increase tension on the way down for a more secure load.

- Add a roping device to provide extra strength as the film is being wrapped at the bottom and top of the pallet

Have more questions? Contact Us.

RELATED INDUSTRIES

The below industries can benefit from the many features of a Handle It semi-automatic stretch wrapping machine.

PHARMACEUTICALS

Keep your pharmaceutical ingredients safe when in transit and storage. Handle It pallet wrappers will provide a clean and consistent wrap to secure your products.

WAREHOUSE & LOGISTICS

Logistical and warehouse operations receive and devan countless pallets every day. Wrapping barrels, drums, and pails with a pallet wrapper will keep the shipment safe until it reaches its final destination.

FOOD AND BEVERAGE

Transporting and storing food and beverage products on pallets requires a semi or fully automated pallet wrapper to help ensure no spills occur.

MANUFACTURING

Handle It pallet wrappers can alleviate the manual labor required to wrap barrels, drums, and pails at your manufacturing facility. Regardless of size, shape, or weight, you can securely wrap your pallets for shipment with precision and consistency.

OIL AND GAS

Oil and gas products pose a hazardous risk if they topple over during transport or storage. A Handle It pallet wrapper will help to ensure your products stay on the pallet while preventing costly spills.

BREWERIES

Whether you’re transporting hops or getting your suds to market, a Handle It semi or fully automatic pallet wrapper will help to secure the load and prevent damage or spills.

HELPFUL RESOURCES

Learn more about Handle It stretch wrappers and accessories through the following resources:

Accessories & Safety Essentials

Brands We've Helped

Recent Projects

Overcoming Pallet Wrapping Challenges for an Industrial Wire Manufacturer

Handle It recently completed a custom manufacturing and installation job that supplied eight flagship pallet wrappers to an industrial wire manufacturer with different warehouse locations throughout the U.S.Eliminating Hand Wrapping of Pallets for Online Cutlery Provider

An eCommerce cutlery company that was manually wrapping pallets contacted Handle It for help solving a warehouse inbound inventory challenge that was creating a bottleneck and costing them a tremendous amount of money and man-hours.Enabling use of Breathable Stretch Wrap Film for an Agricultural Fresh Vegetable Supplier

An agricultural grower and wholesale supplier of onion sets and garlic bulbs in the mid-west replaced an older pallet wrapping machine with the Handle It Model 800 XHT that uses breathable film to keep their products fresh

Success Stories

As you know Houston Wire & Cable purchased 8 (C1901601M) Stretch Wrap Machines along with the standard ramp, for our facilities throughout the country. HWC is very pleased with the quality construction, ease of assembly, and smooth operation of this equipment. None of our 8 facilities have encountered any issues whatsoever with the equipment since our installation. If you are looking for any type of equipment as well as excellent customer service, I would recommend the teams at Handle It and Eastern Lift. They will take care of anything you need.

Pallet Wrappers to Match Your Application

Handle It has a wide range of fully automatic, semi-automatic and mobile robotic pallet wrappers that come with many features that will allow you to improve your shipping efficiency while properly securing your pallets for transport.

Don’t see your industry? Unsure which machine is right for your application? Give us a call or contact us, and one of our friendly experts will work with you to find the best solution.