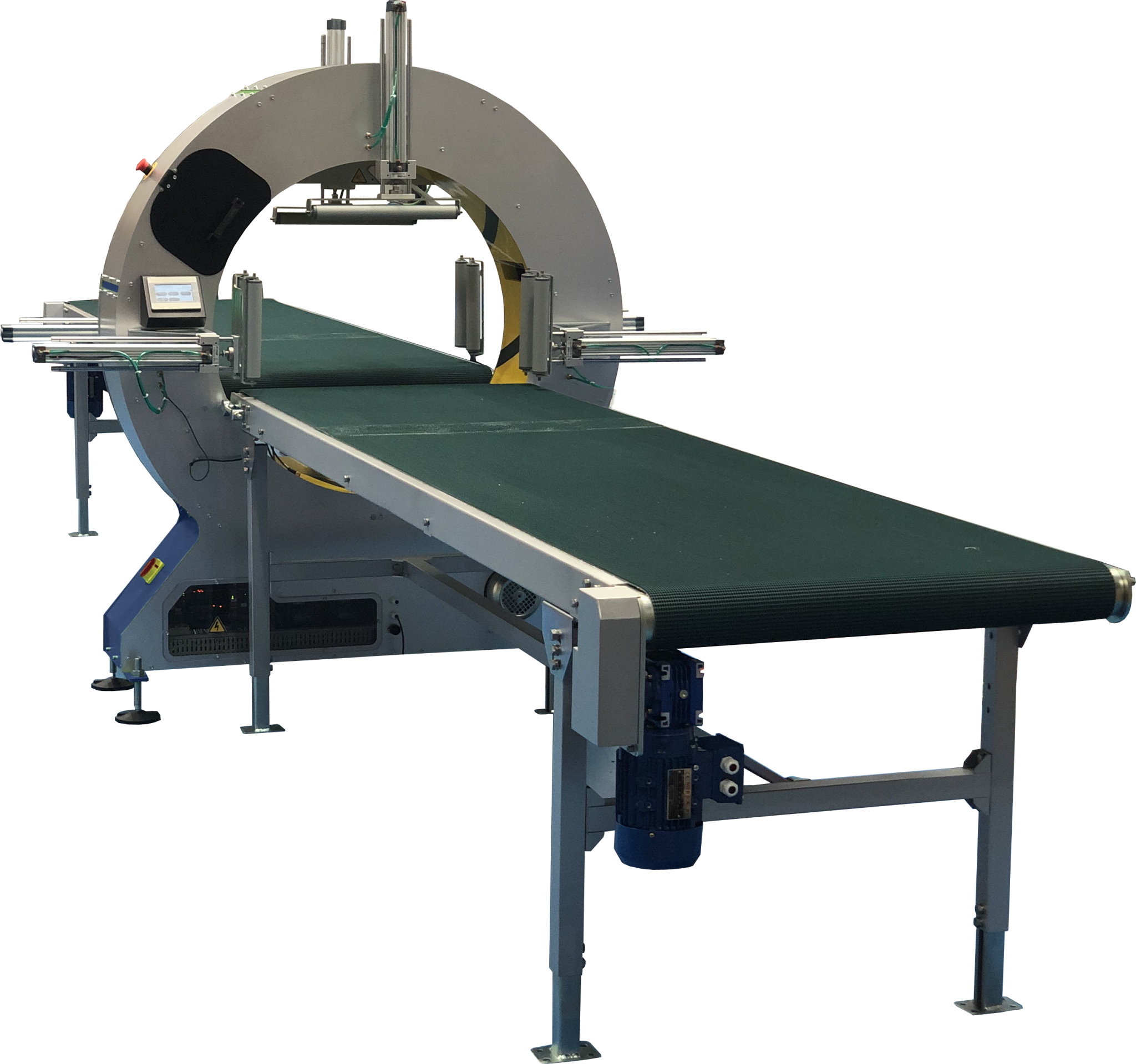

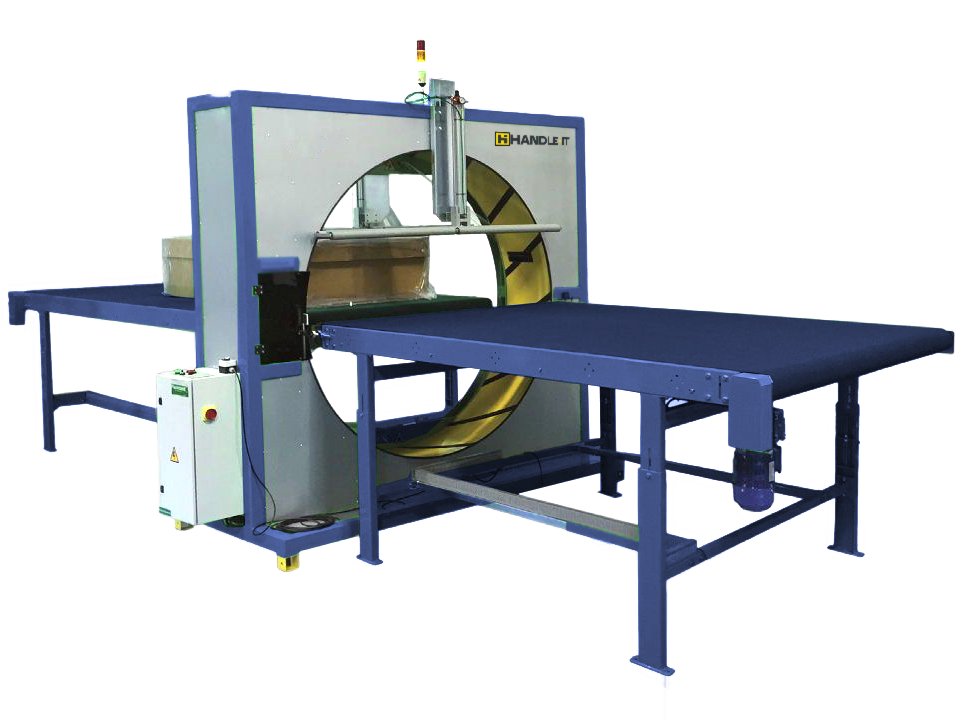

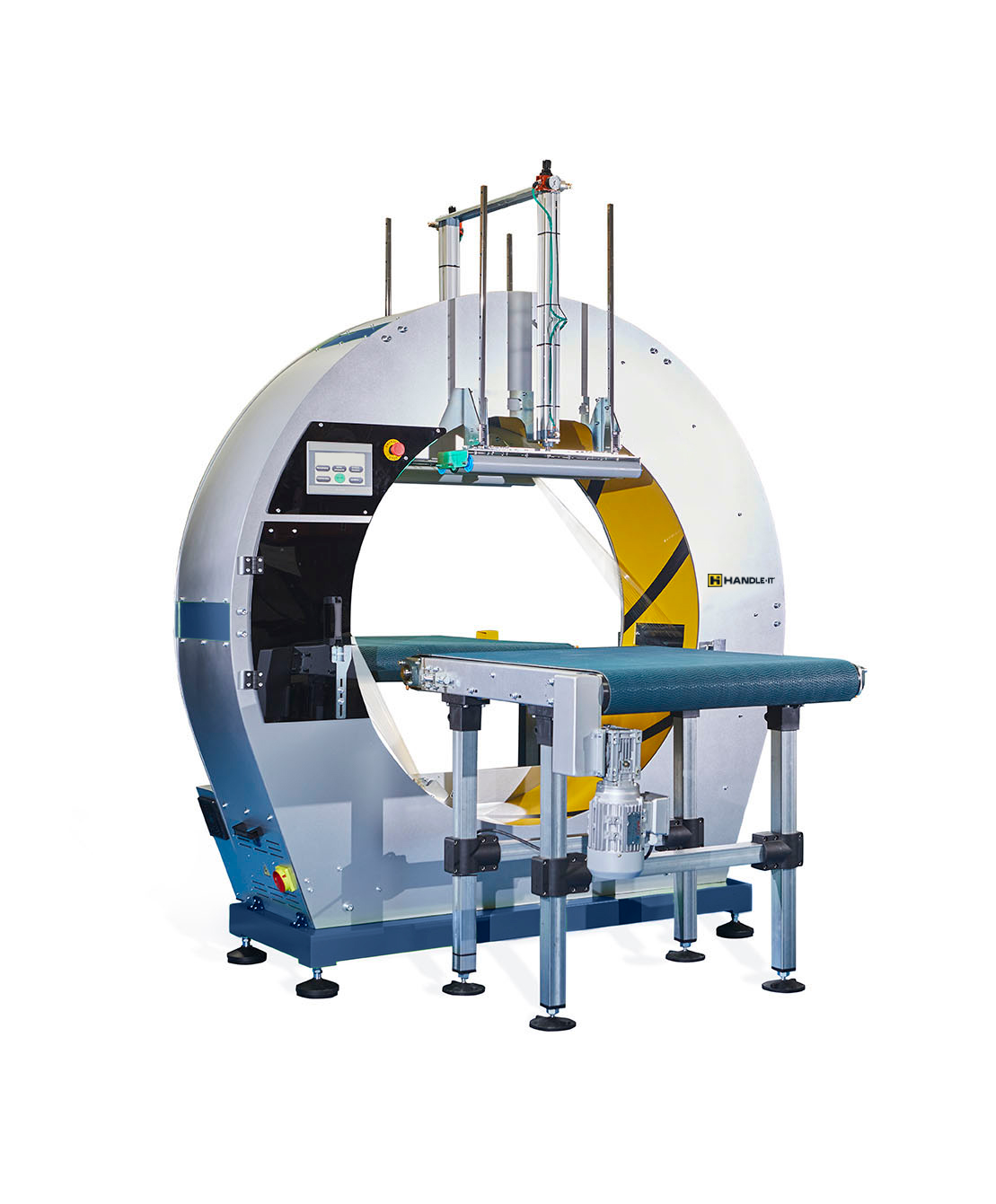

FA-90 Automatic Orbital Wrap Machine

Automatic orbital wrapper used for bundling product with stretch film. Also known as a horizontal stretch wrapper, this machine is ideal for warehouse and manufacturing use. It automatically loads products and threads, wraps, and cuts stretch film. The model OWM-FA-90 is ideal for products like wood molding, flooring, profiles, aluminum bars, pipes, firewood, tubes, blinds, or any other small product needing to be bundled.

Standard dual film reel delivery system gives you faster throughput

Double automatic film cutting and clamp standard with blade protection

Highly customizable to suit your application

Power fed by conveyor and controlled by photocell

Request a Quote

Overview

Standard equipment:

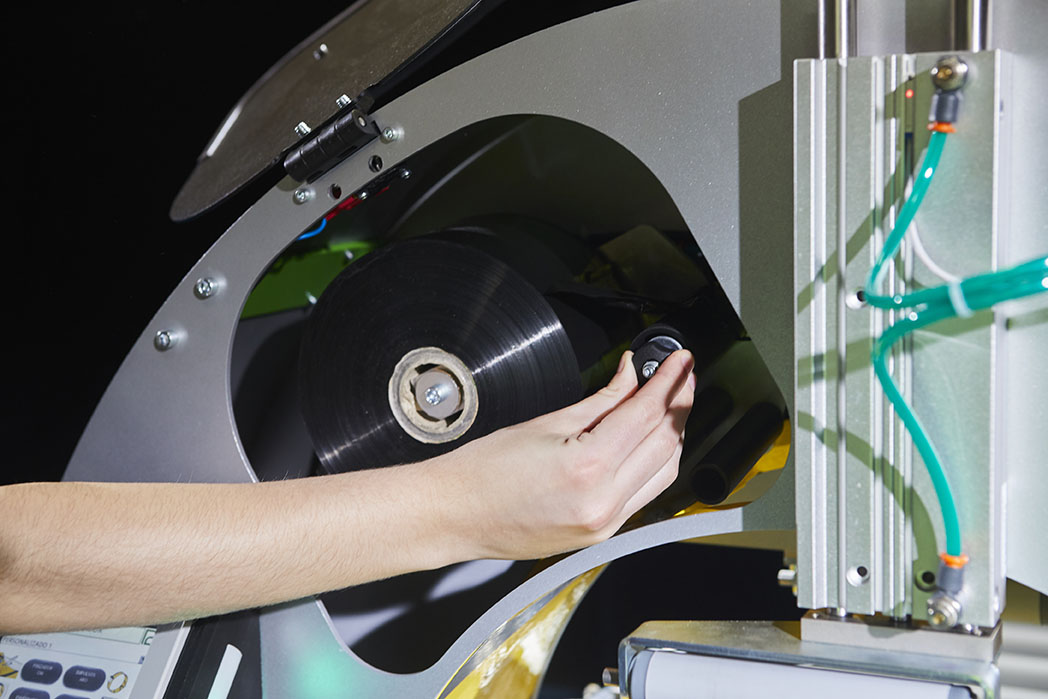

- Double reel dispenser head; allows to wrap with two reels of stretch film for a reinforced wrapping and faster packaging or to wrap with one reel for a simple wrapping; ready to use reels of different width.

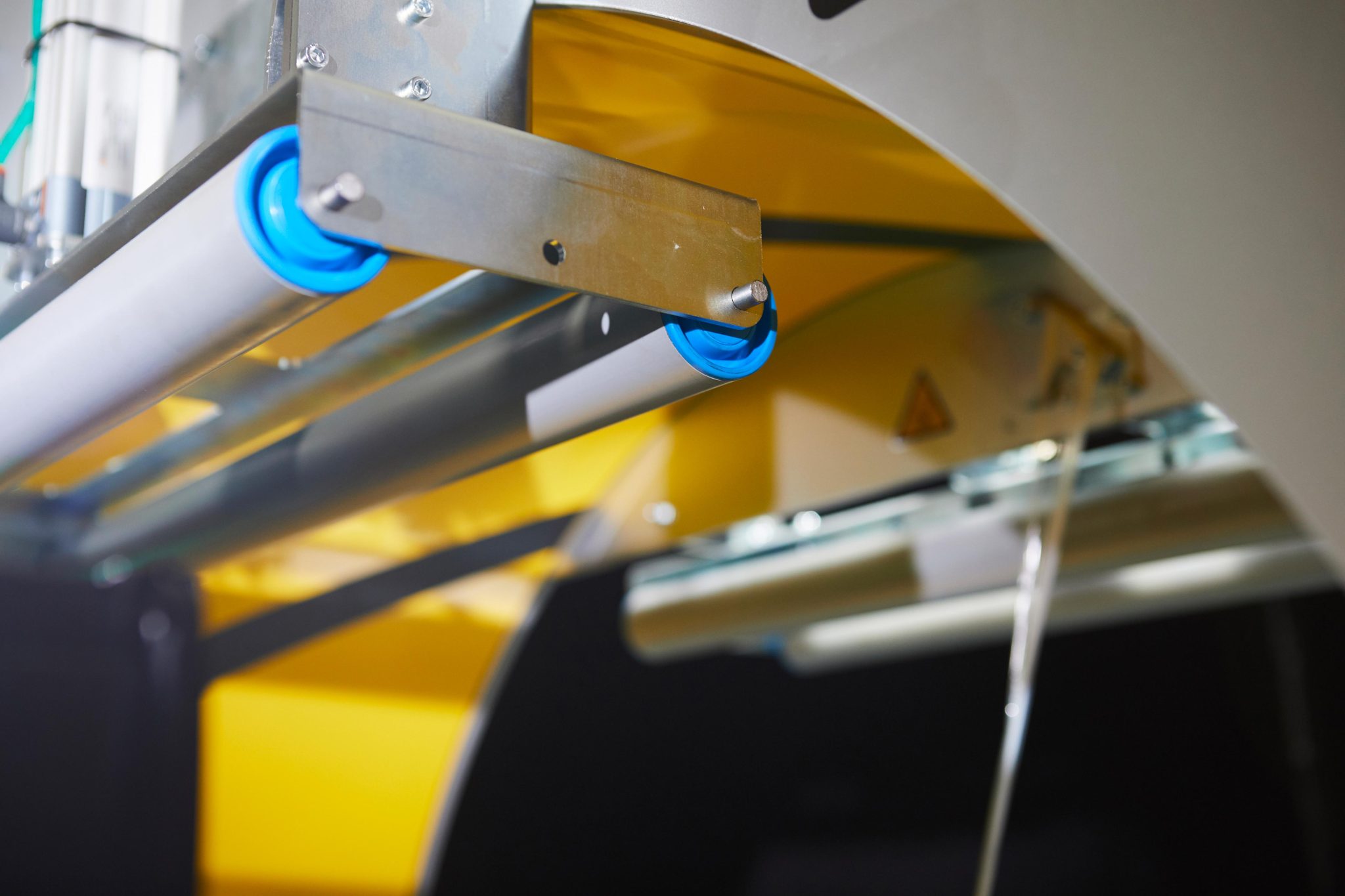

- Fast changing reels without tools and with self-fixing system.

- Adjustable stretch film tension to fit it to the product.

- Double automatic stretch film clamp and cutter system for two reels; cuts even with zero tension and has a blade protector for user safety.

- Automatic stretch film threading for reel changing.

- Stopping system to place the reel dispenser head in the exact position for reel changing.

- Device that unable the machine to work while changing the reel for user safety.

- Ring driver system through trapezoidal belt.

- Ring assembled in the frame, painted in yellow color.

- Steel frame, painted in gray and base in green color

- Ring speed controller to adjust working speed or stretch film overlap onto the product.

- Adjustable extra wrapping laps in both ends of the product for a higher protection.

Interactive color touch screen, integrated in the front of the machine to program and adapt the wrapping machine to the needs of the product to be wrapped with:

- Wrapping programs (9): 1 to 4 – Complete wrapping (from one product end to the other), 5-Only ends, 6-Banding, 7-Complete with intermediate banding, 8-Semi-automatic and 9-Only conveyors.

- Display of messages, explanatory gif videos, change of reel, regulation of extra laps at product ends, on/off top presses (optional), up & down top presses regulation time (optional), distance between banding, warning preventive maintenance and programmable in 3 languages.

- Option to eliminate film tails in the product start.

- Screen lock with password to avoid inappropriate manipulations of the chosen parameters.

- Electrical photocell to start wrapping cycle.

- Integrated electrical cabinet and illuminated with led, to facilitate operations; incorporates master switch.

- Led warning light to inform status of orbital wrapper (operative, working or emergency).

Accessories

Customize your machine:

- Infeed & outfeed top pressers – manual fitting.

- Infeed & outfeed top pressers – automatic fitting, includes electrical photocell to detect product outfeed.

- Rollers side guide – manual fitting.

- Driven conveyor belt W23” x L40” (other dimensions also available).

- Driven conveyor metal rollers W23” x L40” (other dimensions also available).

- Driven conveyor chain W23” x L40” (other dimensions also available).

- Driven conveyor belt with pneumatic lift to place corners W23” x L98”.

- Driven conveyor metal rollers “V” shape W31” x L157”.

- Gravity rollers conveyor + tilter system to place product from vertical to horizontal W47”mm x 59”L

- Table with 4 driven rollers in cross, with pneumatic lift, to wrap round products.

- Table with 2 driven in parallel to wrap round products.

- Hydraulic lift table to center the machine ring vs conveyors.

- Short products bridge <23”

- Driven conveyor belts (bridge) W45” x L23” for short products <23”.

- Wooden/porex blocks automatic dispenser (not included driven conveyor for short products W45” x L23”).

- Warning of stretch film reel end.

- Warning of stretch film breakage.

- Safety fences + safety kit.

- Manual bubble wrap top dispenser (integrated on machine) for reel up to 48”.

- Manual bubble wrap floor dispenser for reel up to 48”W.

Automatic top & bottom bubble wrap reel dispenser up to 48”W Includes:

- ✓ Welding bar by electrical resistances to join the ends of the top and bottom bubble wrap reels.

- ✓ Welding temperature control to adjust the temperature depending on the bubble wrap thickness.

- ✓ Top and bottom bubble wrap reel dispenser; top reel to cover top side product length and bottom reel to cover bottom side product length.

- ✓ Electrical photocell to start automatically the wrapping cycle.

- ✓ Driven feeding of top and bottom bubble wrap reels, to avoid product pulls directly from them.

- ✓ Selector to cancel the automatic dispenser and to allow machine wrapping with stretch film only.

- ✓ Tower lights to inform status of dispenser.

Specifications

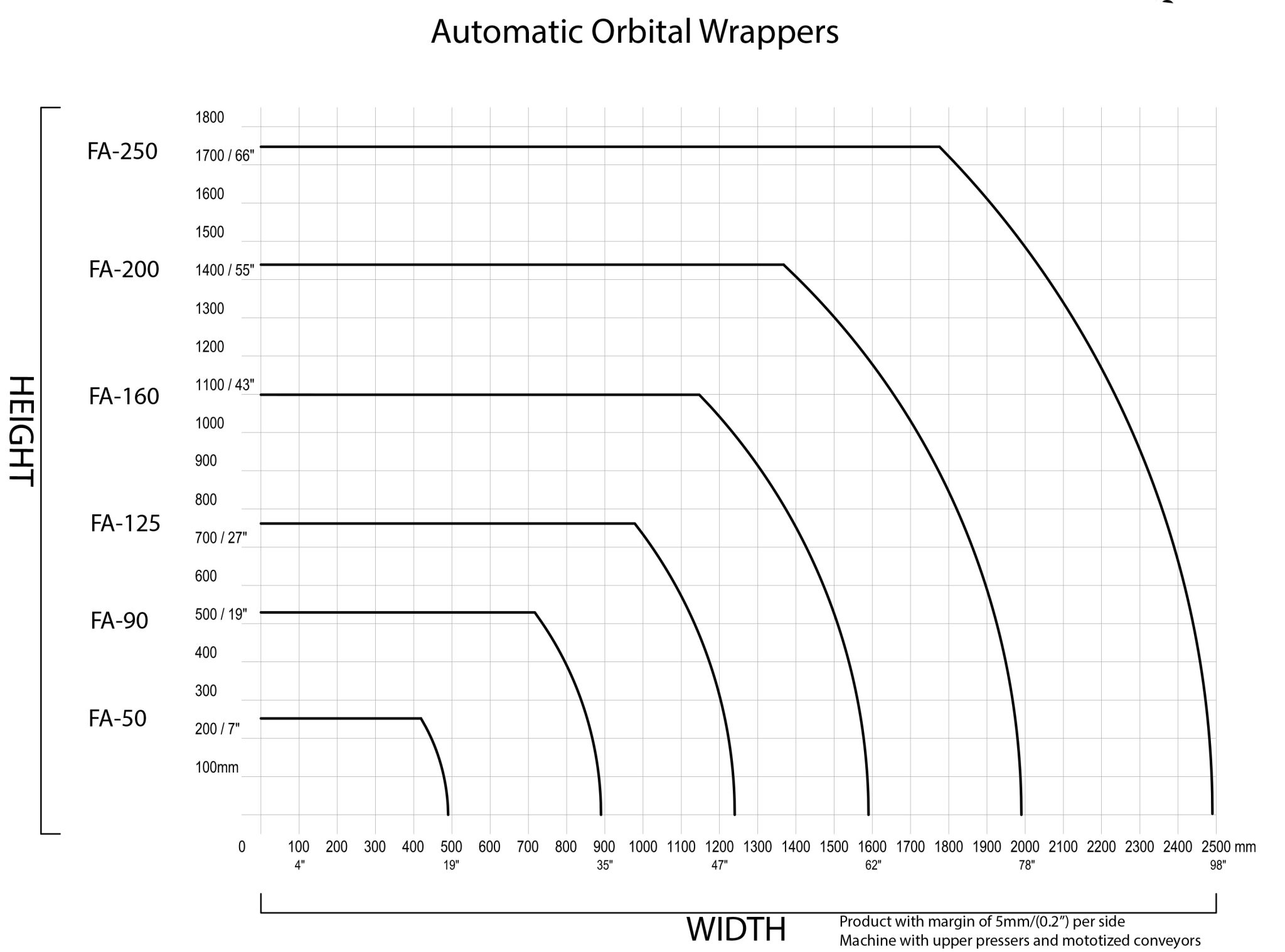

Product to wrap sizes:

- Maximum / minimum length unlimited / 19.6″/500 mm.

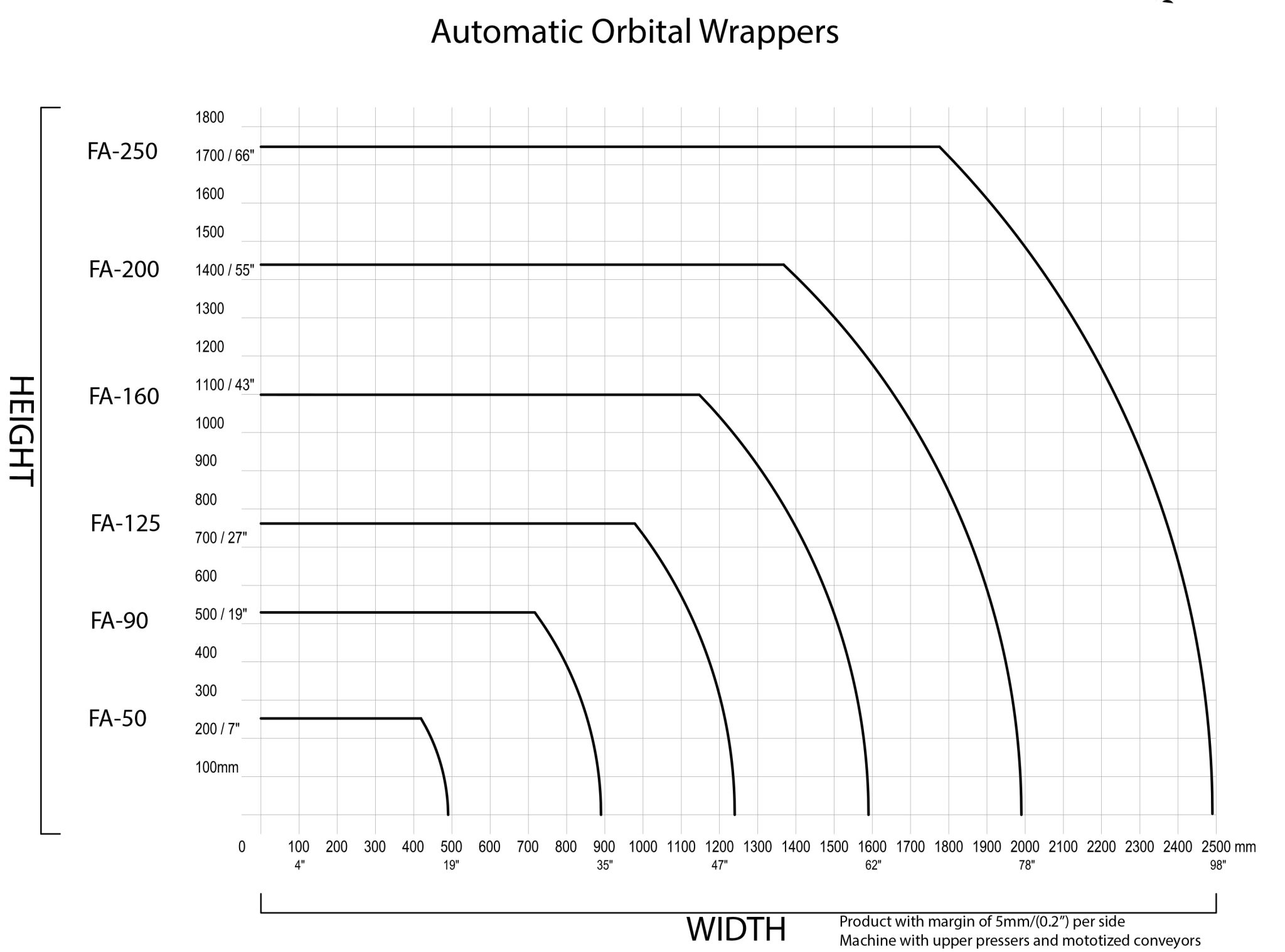

- Other sizes Check with graphic.

- Minimum sizes

7.87″/200 x7.87″/ 200 x 19.6″/500 mm.(L)

Recommended driven conveyor specifications:

- Useful width 23.62″/600 mm.

- Length 39″/1.000 mm.

- Working height adjustable.

- Engine 0.37 Kw*.

- Lineal speed From 13 ft./min. up to 49’/min.

- Max. weight to convey 50lbs/lineal foot.

(*) Speed inverter for inner driven conveyor 0.75 Kw and exit driven conveyor 0.75 Kw.

Electrical equipment:

- Engine 1.5 Kw

- Power supply 110V single phase.

- 24V c.c.

- Power consumption 0.97 Kw

- Ring rotation speed From 5 to 100 rpm.

- Speed inverters Omron.

- Programmable PLC Omron.

- Pneumatic pressure 90 psi

- Compressed air consumption 3 gallons/cycle. Stretchfilm reel specifications:

- Film Width 4″ or 6.5″

- Thickness 17, 23 or 30 microns.

- External / internal Ø 7.87″ / 1.5″

Review the chart below to choose the proper size wrapper for your products

× ![]()

Guarantee/Warranty

The Model FA-90 has a 2-year warranty. For any service-related questions, please call and our technicians will be happy to assist.