Investing in a stretch hooding system is a significant decision for any business looking to optimize its packaging process. At Handle It, we understand that selecting the right packaging solution can be complex. This guide will walk you through the critical questions to consider when evaluating a stretch hooding system for your operation.

Stretch hooding is an excellent end-of-line packaging solution for numerous industries and applications. Consider these key indicators that suggest it might be ideal for your business:

Stretch hooders use durable, multilayer film that is waterproof and provides UV protection, making them perfect for safeguarding sensitive or heavy, irregularly shaped products. Additionally, because the film doesn’t require heat to shrink, it’s a safe choice for temperature-sensitive items, preserving their integrity during packaging. Because stretch hooding uses a single, continuous piece of film, it can be custom-printed with your company’s branding to enhance product visibility and create a professional, cohesive look during transport. Stretch hooding applies the exact amount of film needed for a project, reducing your consumables; in some situations, it also uses less energy than other end-of-line packaging methods.

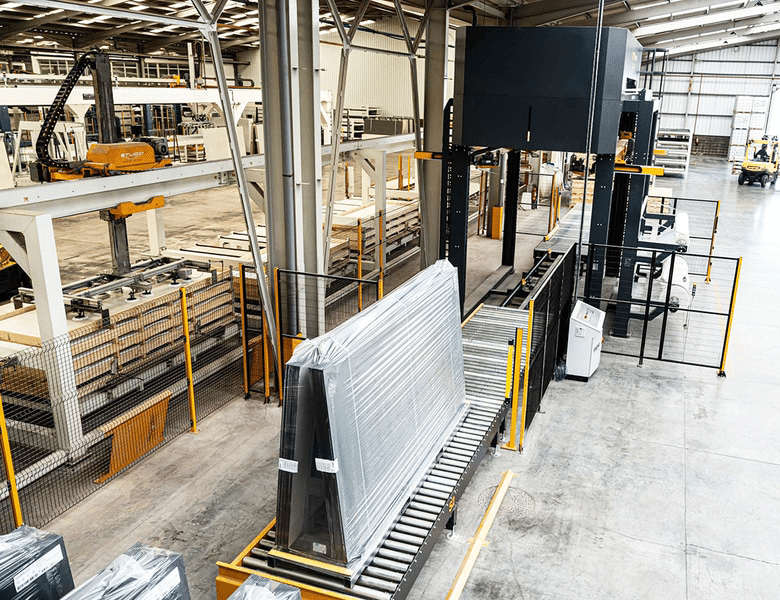

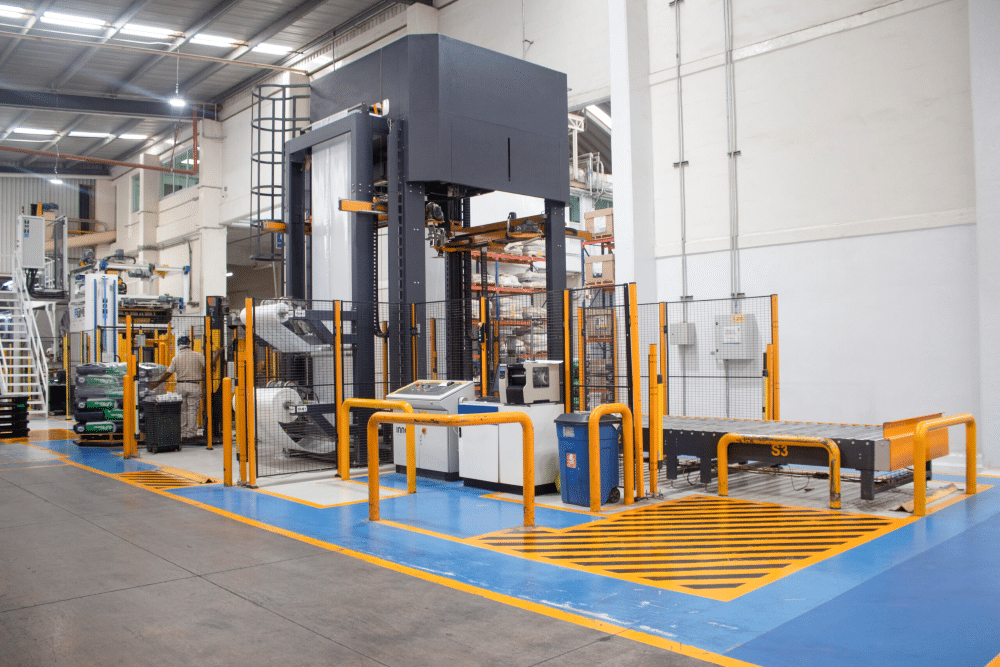

Stretch hooders are also designed for high-volume packaging applications with the Stretch Hooder Core capable of wrapping 120 pallets/hour and the Stretch Hooder Max, designed for larger products (up to 150 x 50 inches), capable of wrapping 70 pallets/hour.

Flexibility is crucial, particularly for businesses that need to wrap irregularly shaped products. Most modern stretch hooding systems can accommodate:

Pro Tip: Always confirm the exact specifications with your supplier.

At Handle It, we offer customizable solutions to match unique load requirements–we ensure your stretch hooder is tailored to your load requirements. The maximum dimensions of products that can be wrapped by our stretch hooders are listed below:

Stretch Hooder Core:

Stretch Hooder Max:

Film selection can make or break your packaging efficiency and is particularly important for sensitive products. Generally, the film for stretch hooding equipment is made to order, but typically, the customizations would include:

At Handle It, our film provides total protection from weather and environmental elements. It is a multilayer waterproof film that protects against moisture and contaminants and is layered with additives for anti-UV protection. It is stretchable but tear-resistant for added protection and its transparency enables easy barcode and label scanning.

Seamless integration is critical to minimize disruption to your existing operations and prevent additional investment for facility updates. Key integration considerations:

At Handle It, we customize your stretch hooder to ensure it easily integrates with your existing equipment. We provide automatic stretch hooding systems that can easily be adapted to different pallet or product sizes, ensuring minimal downtime and offering high levels of efficiency.

A stretch hooding system is a long-term investment designed to increase your company’s profit. When considering the total cost of ownership, look beyond the initial purchase price to ensure your business maximizes its return on investment.

Cost Factors

|

ROI Indicators

|

Due to the size of the investment, you and your business must be supported by your stretch hooding provider before and after the purchase. Be sure to ask your stretch hooding provider about the following:

Selecting a stretch hooding system is more than an equipment purchase—it’s a partnership. At Handle It, we recommend:

At Handle It, we pride ourselves on offering end-to-end support. We take the time to learn about your unique application and customize your solution accordingly. We then offer continued support throughout the lifetime of your system and are always here to help.

A stretch hooding system can transform your packaging efficiency, but only when carefully matched to your specific operational needs. Take time to assess your requirements, ask detailed questions, and partner with a supplier committed to your success.

Ready to explore how a stretch hooding system can revolutionize your packaging process? Contact Handle It today for a comprehensive consultation.

BACK

Shop our wide variety of pallet wrapping machines and stretch wrappers to improve your current packaging process.

Shop our several types and sizes of orbital wrapping machines to meet your horizontal product bundling needs.

Shop our pallet strapping equipment to secure your products for safe and reliable transport.

Shop our guard rail systems and components to improve the safety of the people, structures and items in your warehouse.

Shop rack & post protectors to decrease the damage to your pallet racks and posts due to impact from forklifts and pallets.