Handle It recently completed a job where they helped a major electronics distributor solve multiple shipping problems at once. The workers in the warehouse were struggling to keep up with the increasing shipping demands and needed a viable solution.

Founded in 1937, Marsh Electronics is a regional industry leader that distributes a wide range of electronic services and components in the Milwaukee, WI, area. As the decades passed, Marsh started to experience growing pains as their warehouse realized they needed a better way of wrapping pallets.

The shipping department at Marsh Electronics found themselves using a 10-year-old Vestil model SWA-48 to wrap their pallets. The wrapping machine has a foot pedal that workers needed to hold down for the turntable to spin.

They then had to manually push a handle up and down to wrap the pallet. This turned into a cross between a contortion act and ballet routine to get a single pallet wrapped. After just 15-30 minutes of wrapping pallets, employees began complaining about back and arm pain.

Maintenance costs on what should have been a very simple-to-use pallet wrapper were also getting too high. Adding to the complexity of the situation was that workers first needed to bring the pallet to a separate scale and then move it a second time so they could wrap it.

Something had to change—the Vestil was way out of its league, and the workers were risking severe injury every time they wrapped a pallet. In February of 2022, management at Marsh Electronics set out to find a solution to their shipping problem.

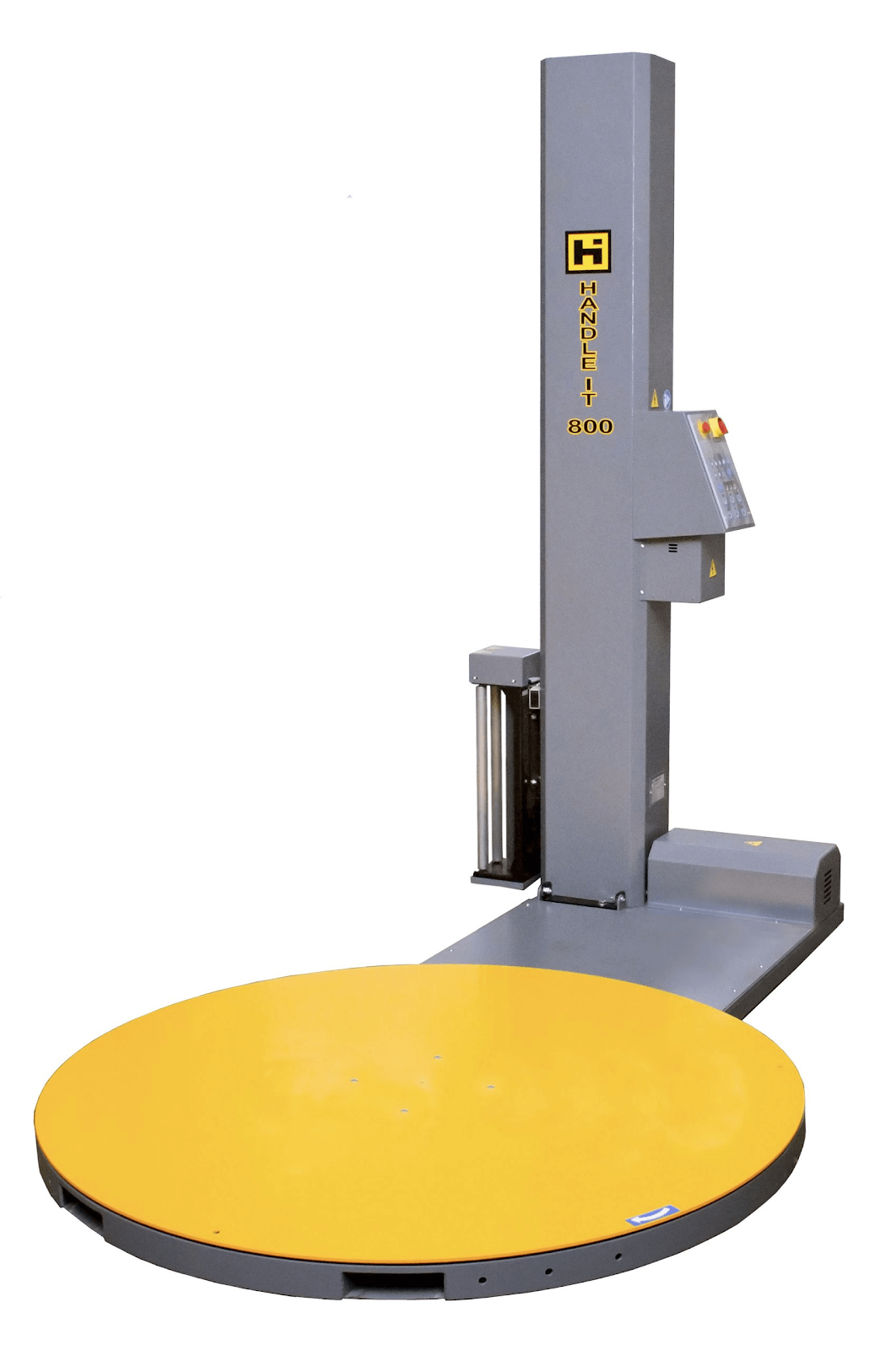

As the pallet loads increased, it became crystal clear that something needed to be done. Marsh Electronics heard about Handle It through a referral from a trusted sales rep. After a discovery call, they settled upon the Model 800 Semi-Automatic Stretch Wrapper, and it was soon on its way.

The Handle It Model 800 is heads and tails more advanced than the antiquated Vestil pallet wrapper that the Marsh shipping department had used for well over a decade.

Instead of a foot pedal and manual levers, workers only had to attach the film to the pallet and push the “Start” button on the Model 800. The machine took care of the rest.

Handle It also integrated an optional state-of-the-art scale, and that solved the problem of having to move the pallet twice to weigh and then wrap it. It’s now one smooth process that shortened the time it took to wrap one pallet.

The Model 800 comes standard with a wide range of standard features, such as:

The shipping department at Marsh Electronics couldn’t be happier with the Handle It Model 800 semi-automatic shrink wrapper—with it, they’ve significantly cut down the time it takes to wrap pallets. The workers no longer have to manually contort their bodies to get the job done right.

Handle It manufactures a wide range of fully and semi-automatic pallet wrappers that will increase efficiency, prevent worker fatigue, and provide a secure and consistent wrap. Check out our list of applications our pallet wrappers can be used for.

Learn why more shipping departments choose Handle It stretch wrappers to wrap their pallets for transport.

Contact one of our experts to learn more

BACK

Shop our wide variety of pallet wrapping machines and stretch wrappers to improve your current packaging process.

Shop our several types and sizes of orbital wrapping machines to meet your horizontal product bundling needs.

Shop our pallet strapping equipment to secure your products for safe and reliable transport.

Shop our guard rail systems and components to improve the safety of the people, structures and items in your warehouse.

Shop rack & post protectors to decrease the damage to your pallet racks and posts due to impact from forklifts and pallets.