Pallet Wrapper Accessories

Handle It offers an extensive range of accessories that will increase the utility of your pallet wrapper. If you’re looking for add-ons and parts that will improve the ROI from your pallet wrapping equipment, we can help.

Efficiency & Ease of Use

Pallet Wrapper with Scale

Scales built into the wrapping machine will give you the exact weight of the complete pallet. This saves a trip to a separate weighing station and saves on space, too. Factory-installed into the unit’s frame, a mast-mounted digital display shows the total weight in easy-to-read digits.

Label Printers

Shrink-wrapped pallets need proper identification in your warehouse and when they arrive at your customer’s location.

A label printer produces an easy-to-apply sticker with the weight and a date/time stamp. We offer model SWS-PRN-DT4X, a 4” label printer.

Auto Film Cut Function

Once the pallet has been wrapped, an auto-cut system slices the film and welds it to the pallet. This saves time and creates a safer working environment by eliminating knives or box cutters in the warehouse.

Loading Method & Oversize Pallet Options

Extra Height for Taller Pallets

Increasing the height of the pallet is a good way of improving space utilization and efficiency.

- Model 800 XHT – 98” Max. Wrap Height

- Model 850 PS XHT – 98” Max. Wrap Height

- Model 1100XH – 118″ Max. Wrap Height

- Model 1200ULXH – 118″ Max Wrap Height

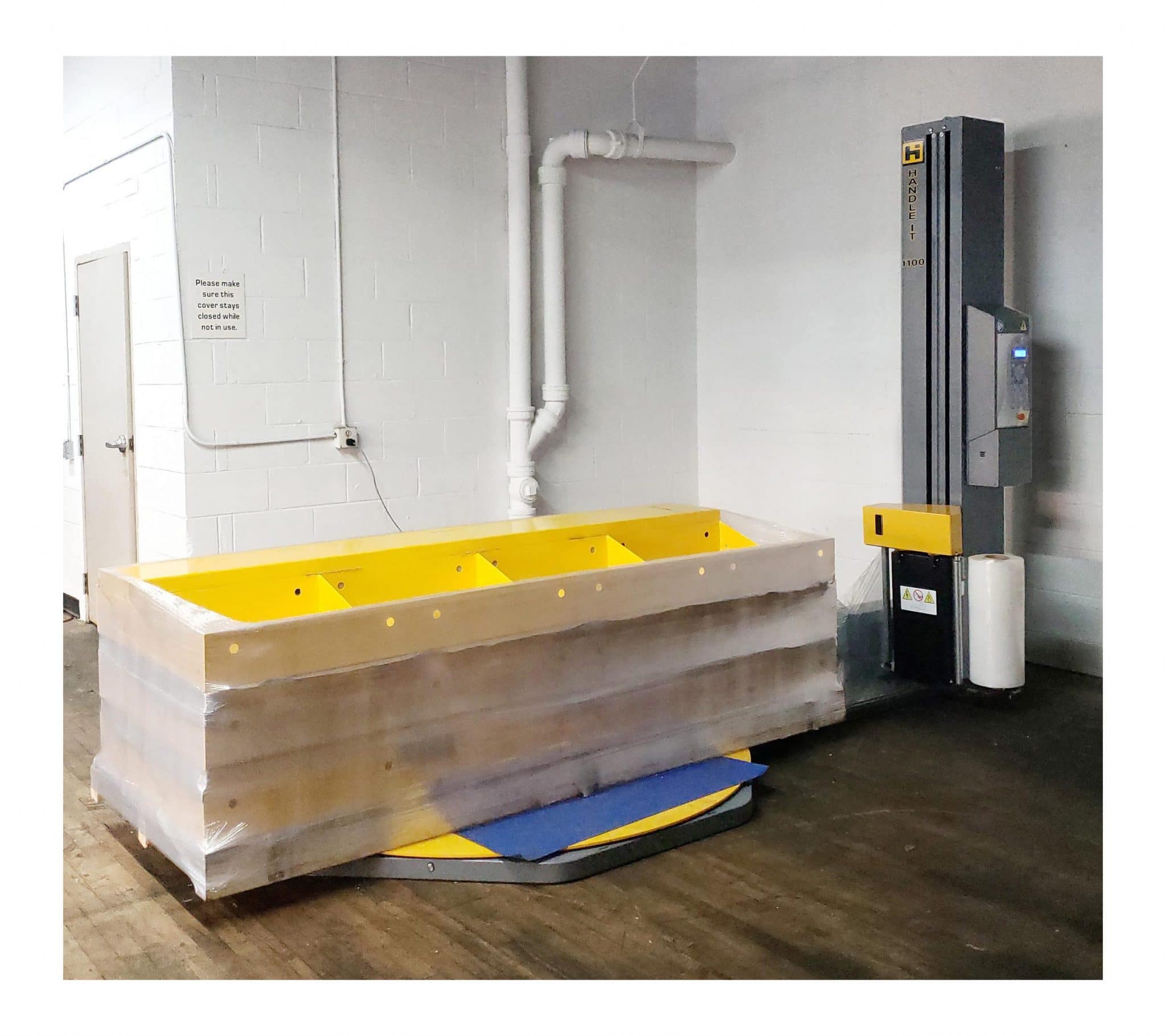

Extended Frame with Larger Turntables

Not every product or package fits neatly within the footprint of a pallet. An extended frame and larger turntable are invaluable for wrapping large items or loads.

Pallet Wrapper Ramp

Pallet wrappers are designed to work with forklift trucks, but sometimes it’s easier to move pallets around with a pallet jack.

Add a deck extension if you are using an electric walk-behind pallet jack.

Unloading a pallet wrapper video.

Load Containment Options

Top Press/Window & Door Clamp

The Top Press and the Door & Window Holder stablize products before they’re wrapped. The Top Press is essential for stabilizing lighter products, cartons, and unstable loads by applying pressure to the uppermost layer, ensuring secure compaction when combined with film wrapping. The Window & Door Clamp provides stability to doors and windows during the wrapping process, keeping them firmly in place. Both accessories enhance the efficiency and reliability of your pallet wrapping operations, ensuring your loads are securely and professionally wrapped every time.

Roping Devices

Pallet wrapping starts and ends with film squeezed down into a rope for added strength.

A roping device performs this automatically at the end of the wrapping cycle, saving time and minimizing waste while ensuring every pallet is wrapped securely.

Tilted Carriage

On models 1100, 1200UL, & 1100AA-C, the carriage can be mounted at an angle. By tilting the carriage, the film band will be applied even lower on the pallet than with standard positioning. Securing the film down further on the pallet board helps to ensure that the load does not slide off of the pallet.

In addition to tilting you can also add a film roping bar. This will curl up the bottom edge of the film which greatly improves tear resistance and adds an even stronger connection to the pallet.

Environmental Options

Cold Storage Specification

Low temperatures, like those found in many food storage warehouses, aren’t friendly to regular lubricants and moving parts.

Specify you will be using the shrink wrapper in a cold storage environment, and we will equip it with components and lubricants engineered to perform in the cold.

Anti-Static Brush

Feeding stretch film generates a lot of static, especially in cold, dry environments. This brush dissipates the static so workers don’t get shocked, and it eliminates risks to the product.

Special Photo Eye Sensor

Upgraded photo eyes allow you to wrap products that are dark, black, or also reflective loads.

Safety Options

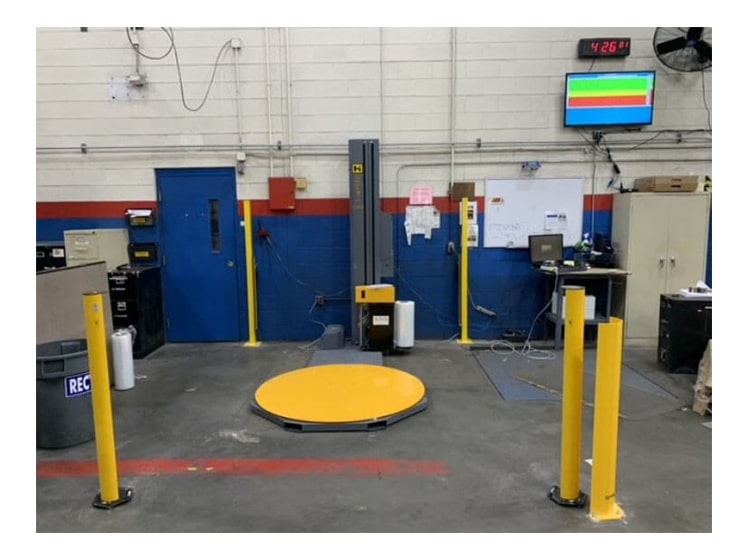

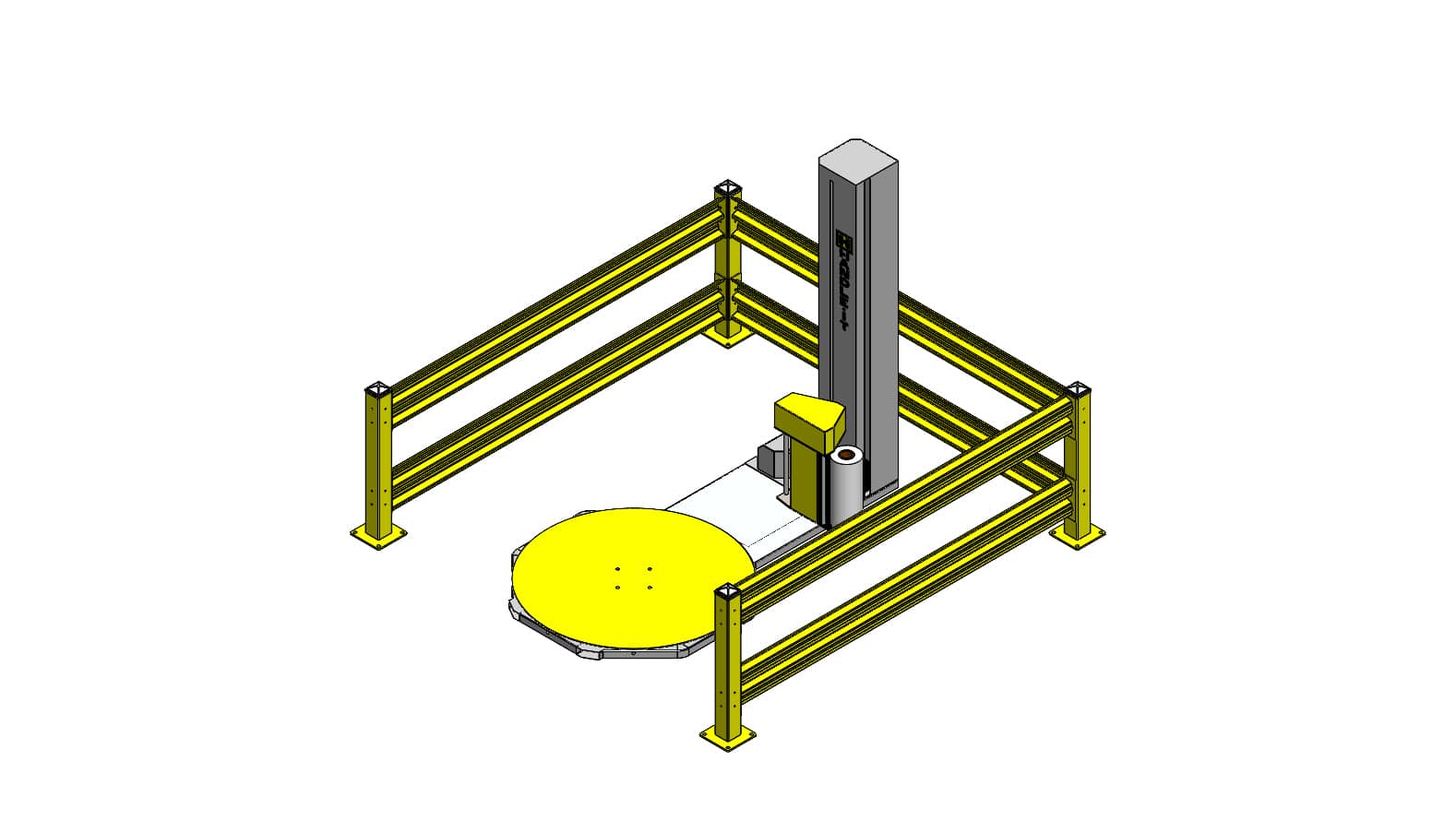

Industrial Safety Fencing and Light Curtains

Protect your workers and equipment by placing machine fencing or a sensing infrafed light curtain that will shut down machinery quickly if the perimeter is compromised.

Forklift Wheel Stop

Fork Lift Wheel Stops are a simple, effective tool that prevents forklifts from bumping into or driving on stretch wrapper turntables.

This durable & long-lasting piece can save thousands of dollars when factoring in repairs to damaged machines and lost production with downtime.

Stretch Wrapper Guard Rail Protection Kit

Warehouse Guard Rail packages are a great way to protect your stretch wrapper from forklift damage as well as to keep pedestrian traffic from walking into an area when a machine is wrapping.

Available in two sided and three sided protection options with standard 10‘ lengths and can be manufactured in any 1’ increment size.

Other Accessories

We offer other accessories, including a window and door wrapping package, that can help simplify and improve your pallet wrapping operation. If you don’t see an accessory or special feature listed above, please contact us.

We specialize in pallet wrappers and can assist you in finding the right accessories to improve the productivity and efficiency of your warehouse operations.

Companies we’ve worked with

Recent Projects

Case Study: How Handle It Helped an Onion and Garlic Grower Solve a Unique Shipping Challenge

Handle It recently completed a custom semi-automatic pallet wrapping job for an onion and garlic growing company. Learn how we solved their unique challenges.CASE STUDY: Helping an eCommerce Site Solve an Inbound Inventory Challenge

Handle It helped an online eCommerce site with a semi-automatic pallet wrapper that eliminated the need for manually hand-wrapping 50-60 pallets per day.CASE STUDY: Overcoming Pallet Wrapping Challenges for an Industrial Wire Manufacturer

Learn how Handle It helped an industrial wire manufacturer solve a heavy and irregular size shipping problem.

Success Stories

“Our biggest benefits of having the Handle It Stretch Wrapper are ergonomics and speed. Since we’ve started using the unit, there hasn’t been one complaint from our employees about any strain or pain with having to hand wrap pallets. Once that was eliminated, our pallet wrap throughput skyrocketed, and we are able to get a lot more done in a single shift than ever before.”

Let Handle It Help Solve Your Pallet Wrapping Challenges

Handle It has several semi and fully automatic pallet wrapping machine solutions for warehouses of all sizes. The power pre-stretch feature, programmable controls, and slim footprint will help increase your productivity while reducing costs.

Learn why more shipping and receiving operations choose Handle It pallet wrappers to improve efficiency and save money.