Stretch Wrapping Pick and Pack Mixed Products on Pallets

Wrapping pallets of pick and pack mixed products by hand often leads to spilled or damaged products during transport. A semi-automatic pallet wrapping machine from Handle It will provide a safe, secure, and consistent wrap. With the ability to wrap up to 300 loads per day, you’ll save time and money while preventing worker’s comp claims due to workers suffering from repetitive motion injuries.

Handle It stretch wrappers offer a wide range of standard features that will improve efficiencies when stretch wrapping mixed pick and pack product on pallets:

- Storage of up to 32 end-user programs

- Up to 250% power pre-stretch

- 118″ maximum load wrap height

- User-friendly control panel

- Ability to wrap up to wrap heavy, unstable, or tall loads

- Safer and easier loading and unloading

Recommended Products

3000 SERIES MOBILE STRETCH WRAP MACHINE

The Handle It Model 3000 mobile stretch wrap machine is ideal for heavy, long, or unstable pallet loads. The heavy-duty battery allows you to wrap up to 200 loads per charge.

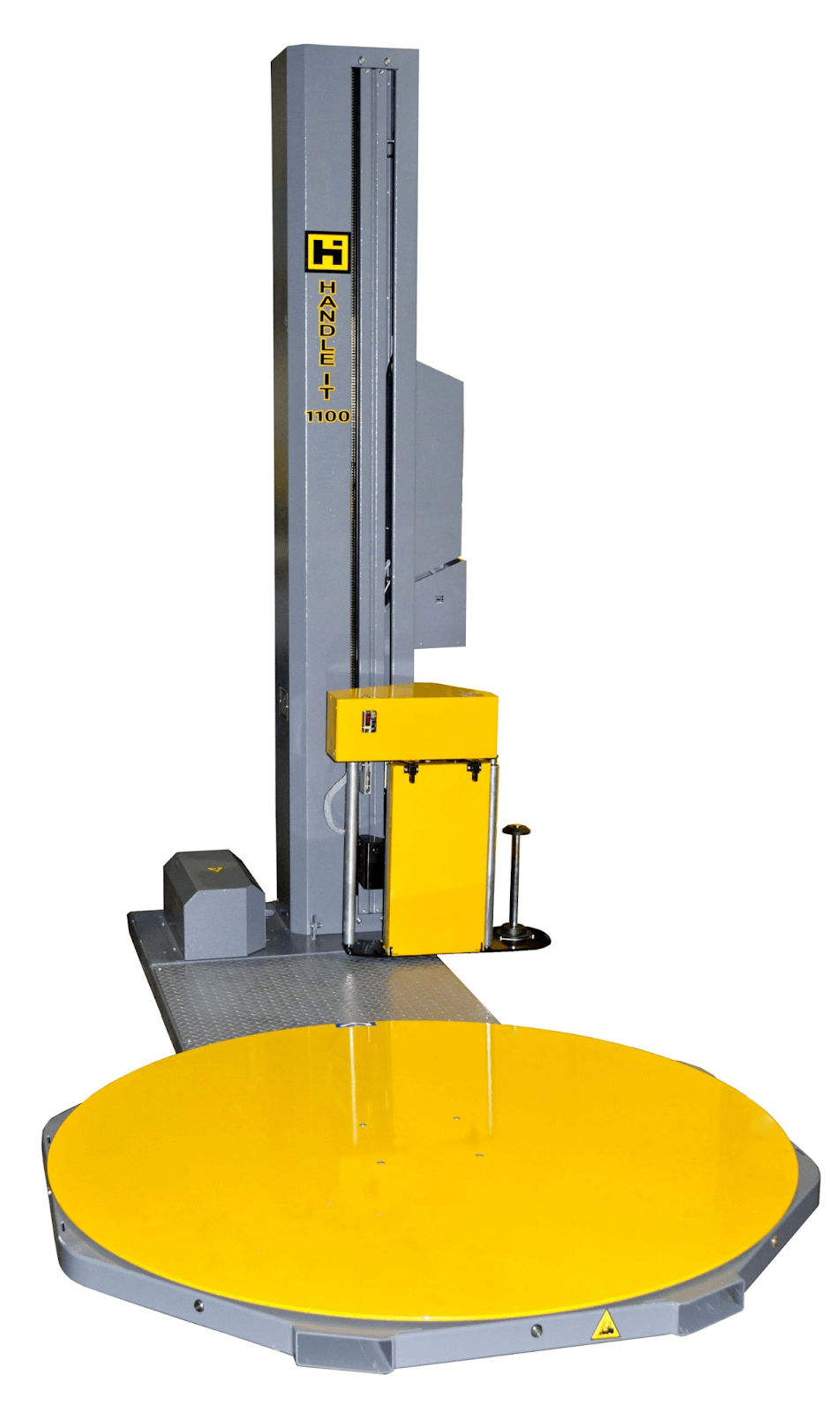

1100 SEMI-AUTO TURNTABLE STRETCH WRAP MACHINE

With the ability to wrap up to 300 oversized pallets daily, the Model 1100 semi-automatic stretch wrapper is ideal for high-volume shipping departments.

1200UL ULTRA LOW PROFILE STRETCH WRAP MACHINE

The small footprint of the Handle It Model 1200UL allows for more efficient use of floor space. The patented ultra-low frame (.75”) enables workers to load from three sides without using a long ramp.

Pro Tips

Here are several Pro Tips that will help you properly stretch wrap mixed pick and pack products on pallets:

- A great starting point is a cycle with 2-3 top and bottom rotations with a film tension of around 50% for average pallet loads.

- On initial setup, try slower speeds and less tension, and work your way up to optimize cycle time and load containment.

- If you have sharp product edges, try lower film tension and rotation speed or consider a thicker, more puncture-resistant film.

- For outlier products at the top, try increasing the overwrap delay or “flanging” time along with top rotations to make sure you get the film band high enough to catch the top layer. This can be especially helpful with pick and pack operations when the top of the pallet might have a few boxes in the center of the stack.

- If you have empty spaces or voids, try either increasing the flanging time or trying the fixed height setting available on the model 1100.

RELATED INDUSTRIES

The below industries can benefit from the many features of a Handle It semi-automatic stretch wrapping machine.

RETAIL COMMERCE

Help ensure the safe transport and delivery of your pick and pack mixed products to retailers and other big-box stores. Plastic wrapping mixed box pallets can help reduce the chances of damaged merchandise while in transit.

WAREHOUSE & LOGISTICS

Logistical and warehouse operations receive and devan countless pallets every day. Wrapping pick and pack mixed box pallets with a pallet wrapper will keep the shipment safe until it reaches its final destination.

E-COMMERCE FULFILLMENT CENTERS

Ensure the secure transport of your customer’s pick and pack mixed products with a fully or semi-automatic pallet wrapping machine. The 250% power pre-stretch allows for up to 50% savings in stretch wrap usage.

MANUFACTURING

Handle It pallet wrappers can alleviate the manual labor required to wrap mixed box pallets at your manufacturing facility. Regardless of size, shape, or weight, you can securely wrap your pallets for shipment with precision and consistency.

HELPFUL RESOURCES

Learn more about Handle It stretch wrappers and accessories through the following resources:

Accessories & Safety Essentials

Related Articles

- Pallet Wrapper Preventative Maintenance Guide

- Stretch Wrapper Safety Guide

- Case Study: Helping an eCommerce site solve an inbound inventory challenge

- CASE STUDY: Overcoming Pallet Wrapping Challenges for an Industrial Wire Manufacturer

- Top 3 Reasons Why You Need a Pallet Wrapping Machine if You’re Currently Hand-Wrapping

Brands We've Helped

Recent Projects

Overcoming Pallet Wrapping Challenges for an Industrial Wire Manufacturer

Handle It recently completed a custom manufacturing and installation job that supplied eight flagship pallet wrappers to an industrial wire manufacturer with different warehouse locations throughout the U.S.Eliminating Hand Wrapping of Pallets for Online Cutlery Provider

An eCommerce cutlery company that was manually wrapping pallets contacted Handle It for help solving a warehouse inbound inventory challenge that was creating a bottleneck and costing them a tremendous amount of money and man-hours.Enabling use of Breathable Stretch Wrap Film for an Agricultural Fresh Vegetable Supplier

An agricultural grower and wholesale supplier of onion sets and garlic bulbs in the mid-west replaced an older pallet wrapping machine with the Handle It Model 800 XHT that uses breathable film to keep their products fresh

Success Stories

As you know Houston Wire & Cable purchased 8 (C1901601M) Stretch Wrap Machines along with the standard ramp, for our facilities throughout the country. HWC is very pleased with the quality construction, ease of assembly, and smooth operation of this equipment. None of our 8 facilities have encountered any issues whatsoever with the equipment since our installation. If you are looking for any type of equipment as well as excellent customer service, I would recommend the teams at Handle It and Eastern Lift. They will take care of anything you need.

Pallet Wrappers to Match Your Application

Handle It has a wide range of fully automatic, semi-automatic and mobile robotic pallet wrappers that come with many features that will allow you to improve your shipping efficiency while properly securing your pallets for transport.

Don’t see your industry? Unsure which machine is right for your application? Give us a call or contact us, and one of our friendly experts will work with you to find the best solution.