Features

FEATURES & BENEFITS

- Max load diagonal 82″

- Fixed pedestal mount

- 110V plug-in

- Photo eye auto pallet height sensor

- Power prestretch carriage (up to 250%)

- Safety stop loop at base

- Stop at 0 position

- 6 working cycles

- 32 end user program storage

- Wrapped pallet counter

- Rack & pinion carriage drive track

- Overall dimensions: 125” length x 113” width x 140” height

MAIN OPTIONS

- Adjustable power prestretch carriage (600%)

- Auto-cutoff system

- Roping system

- 118” max wrap height

- Remote control

- Photo cell for dark or reflective loads

- Extended arm for 114″ load diagonal

How Does a Rotating Arm Stretch Wrap Machine Work?

Rotating arm stretch wrappers can wrap a high volume of loads that other machines cannot. The lack of a turntable allows you to place non-standard size and weight pallets on the floor in the wrapping zone via a forklift or pallet jack.

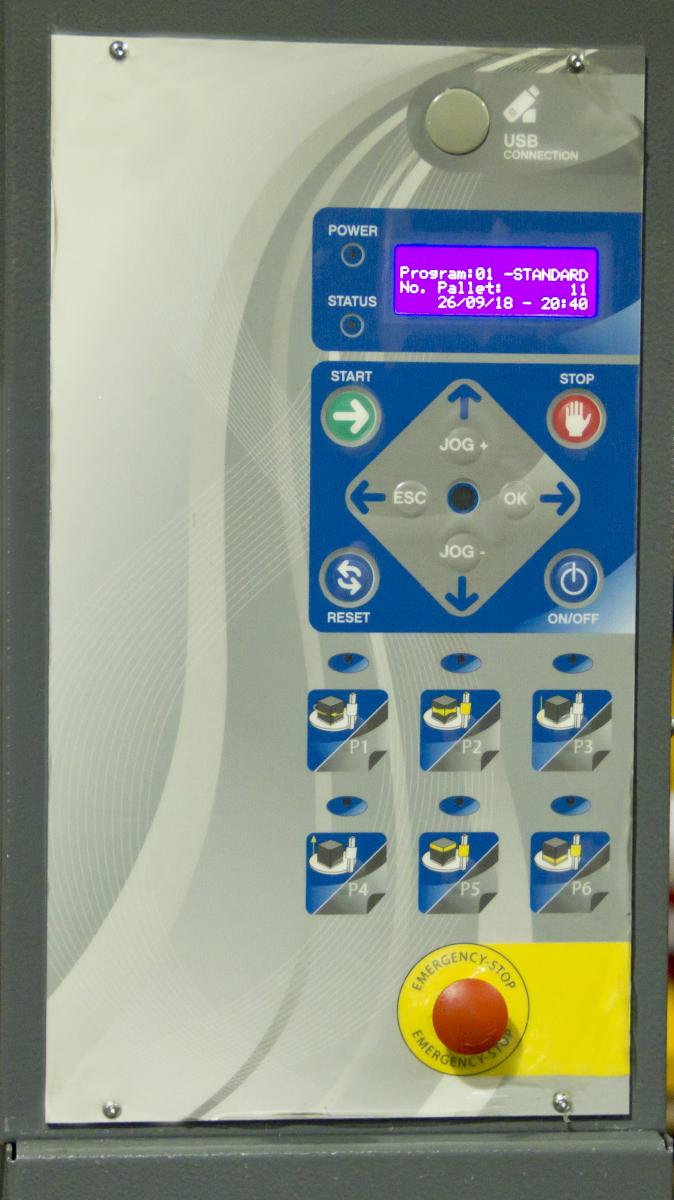

Once the pallet is in place, the operator then pushes a button on the control panel, and the machine immediately begins wrapping the pallet. The rotating arm then follows a preset wrap program to ensure the stability and security of the load.

Depending on the model, the machine can wrap anywhere from 25 per hour up to 300 per day.

Benefits of Rotary Arm Stretch Wrap Machines

A rotary arm stretch wrap machine allows the pallet to remain stationary during the wrap cycle. This offers several advantages:

Extremely Light Loads—On a standard turntable pallet wrapper, very light loads can fall off during the wrapping process. A rotary arm machine allows the pallet to remain securely in place, thereby preventing the load from spilling.

Extremely Heavy Loads—Turntable pallet wrappers have a max load weight. Rotary arm stretch wrappers do not have a turntable and, as such, no weight limit.

Washing Issues—Some shipping areas require regular washdowns. You can raise the rotary arm of the wrapper to avoid it getting wet during the cleaning process.

Unstable Loads—You run the risk of spilling or damaging an unbalanced load if you put it on a turntable wrapper. Rotary stretch wrap machines do not have turntables and can quickly wrap non-standard size pallet loads.

Tall Loads—Taller loads run a risk of getting damaged when using a turntable stretch wrapper. A rotary arm stretch wrapper allows for the wrapping of much higher pallets.

Handle IT 2200 vs. Top Competitors (PRTW-2150, Flex RTD, S-300)

The Handle It 2200 rotating arm stretch wrapper can help you wrap oversized, bulky, or unstable pallets. There are several other comparable models on the market:

- PRTW-2150

- Flex RTD

- S-300

All four machines are designed for heavy or unstable loads. They come with a standard power pre-stretch feature that helps save on film costs. However, there are a few variations between the models:

| Model # | Handle It 2200 | PRTW-2150 | Flex RTD | S-300 |

|---|---|---|---|---|

| Loads Per Hour | 300 per day | 45 per hour | 30-40 per hour | 25-35 per hour |

| Max Wrap Height | 118” | 116” | 80” | 80” |

| Diagonal Load | 82” | 80” | 74” | 76” |

| Machine Size | 125” L x 113” W x 140” H | Not Available | 172” L x 156” W x 115” H | 172" L x 157" W x 121" H |

| Power Pre-Stretch (standard) | 250% up to 600% | 245% | 260% | 200% |

| Photo Eye | Yes | Yes | Yes | Yes |

| Arm Rotation Speed | 12 RPM | 14 RPM | 16 RPM | 15 RPM |

| Max Load Weight | Unlimited | Unlimited | Unlimited | Unlimited |