Overview

Performance

- 300 maximum average loads per day.

- Production rate of around 2 minutes per pallet.

- 86″ maximum load wrap height (with room for overwrap) -118″ extended height available.

- 4400lb maximum load weight capacity.

- 250% power pre-stretch film carriage for improved efficiency.

- Remote controlled auto film attach, hot weld seal, and film auto cut. -Operator never leaves the forklift.

Features

- Photocell for pallet height detection.

- Remote control for cycle start, no need to get off the forklift the machine automatically attaches, seals, and cuts the film.

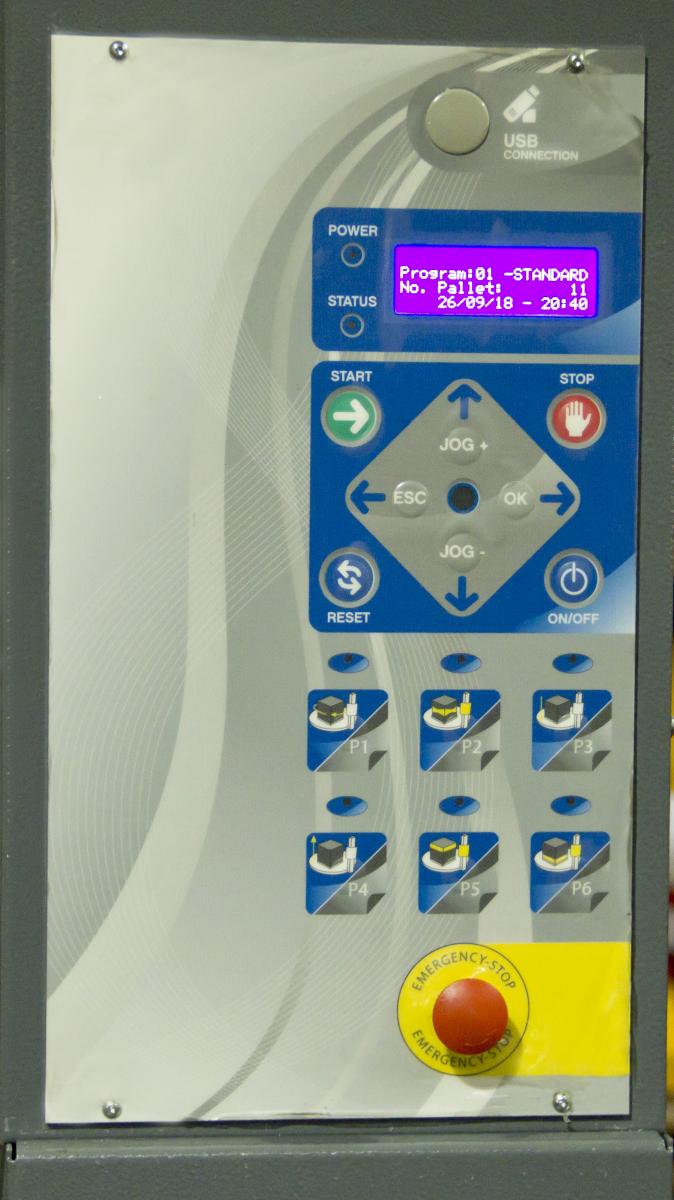

- Easily adjustable parameters such as bottom wraps, top wraps, carriage ascent & descent speed, film tension, & starting wrap height.

- USB port to upload software and download settings, reports, and statistics.

- 6 working cycles: ascent/descent, topsheet, only ascent, only descent, layers, and stack.

- Storage of 32 end user programs.

- On-board diagnostics.

- Up to 250% film pre-stretch with electronic power pre-stretch motor.

- 3 year warranty.

| 1100AA-C | The Competition | What's The Difference |

|---|---|---|

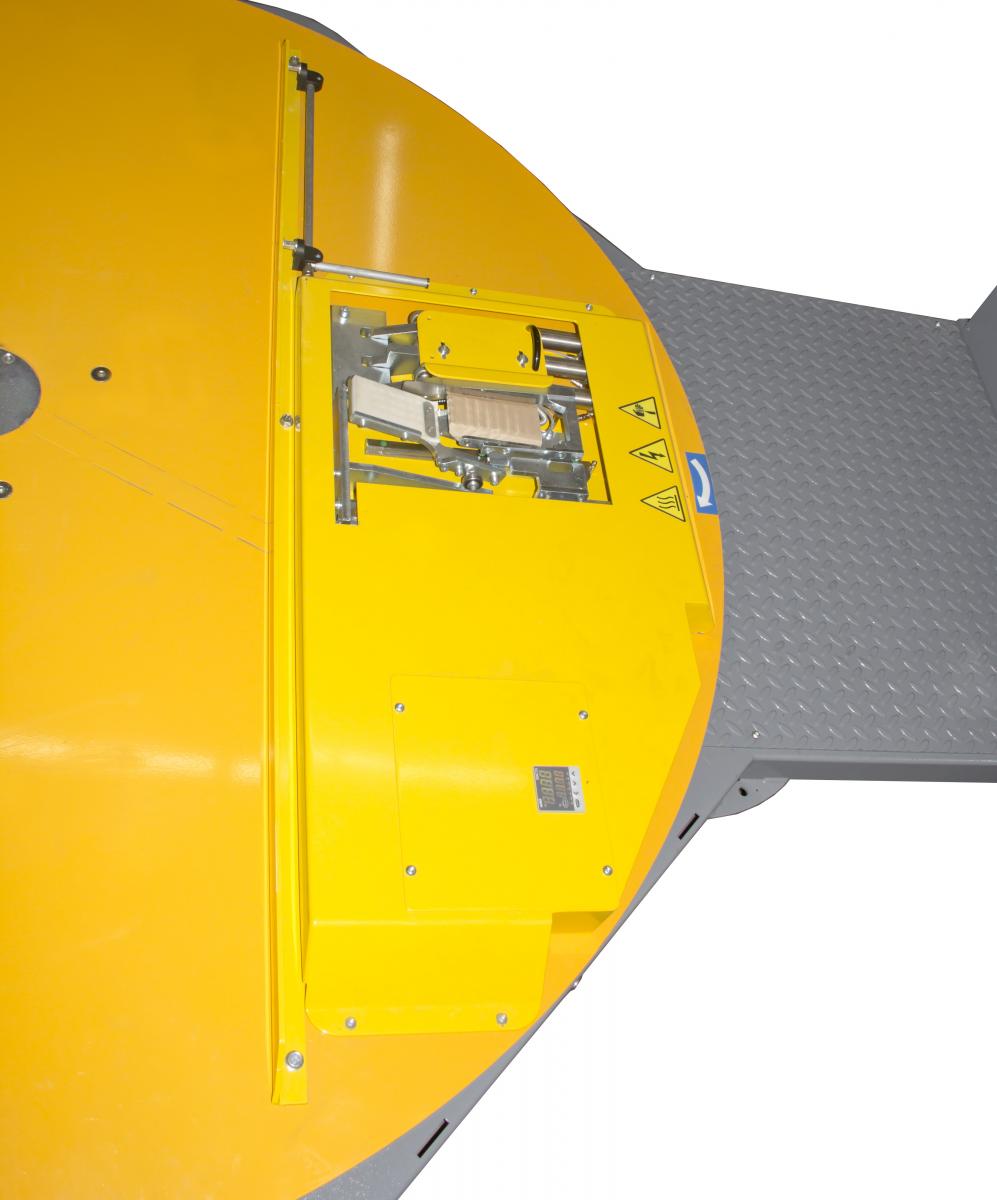

| 2-Step Tail Treatment | Ineffective Tail Treatment | The 1100AA-C uses a 2-step tail treatment process to effectively secure your loads. It ropes and welds the end of the film to ensure the pallets integrity. Other machines simply wipe, or leave the tail untreated. This can compromise the quality of the wrap or unravel during transit. |

| Onboard automatic system | Outboard automatic components | The 3-in-1 automatic system on the 1100AA-C is fully integrated into the turntable. The slim profile reduces the chance of damage during loading. Machines with outboard arms commonly experience this sort of damage. |

| Roped Tail Treatment | Bare Tail Treatment | The tail end of the wrap is formed into a strand, or rope, and then is sealed Bare Tail Treatment to the load. Roped film is many times stronger than it would otherwise be. This gives a tail treatment that is tight, strong, and secure. |

| Easier Loading | Loading requires precise placement | The 1100AA-C system will work even if the pallet isn't loaded perfectly or the load isn't fully uniform.The competition can struggle if the pallets aren't in the perfect position. |

Benefits

- Rack and pinion carriage drive system increases reliability and decreases down time.

- Electronically controlled power pre-stretch film carriage- load sensor dynamically controls the application of film for an ultra consistant film stretch.

- Integrated PLC controls with onboard diagnostics make repairs easier to identify and reduces downtime.

- Belt driven power pre-stretch carriage for added reliability.

- Heavy Duty carriage rollers and self lubricating turntable bearings.

- Mirror included to spot location when loading.

- Password protection and one of the widest array of wrap cycle parameters available.

Check out our application videos on Youtube