Overview

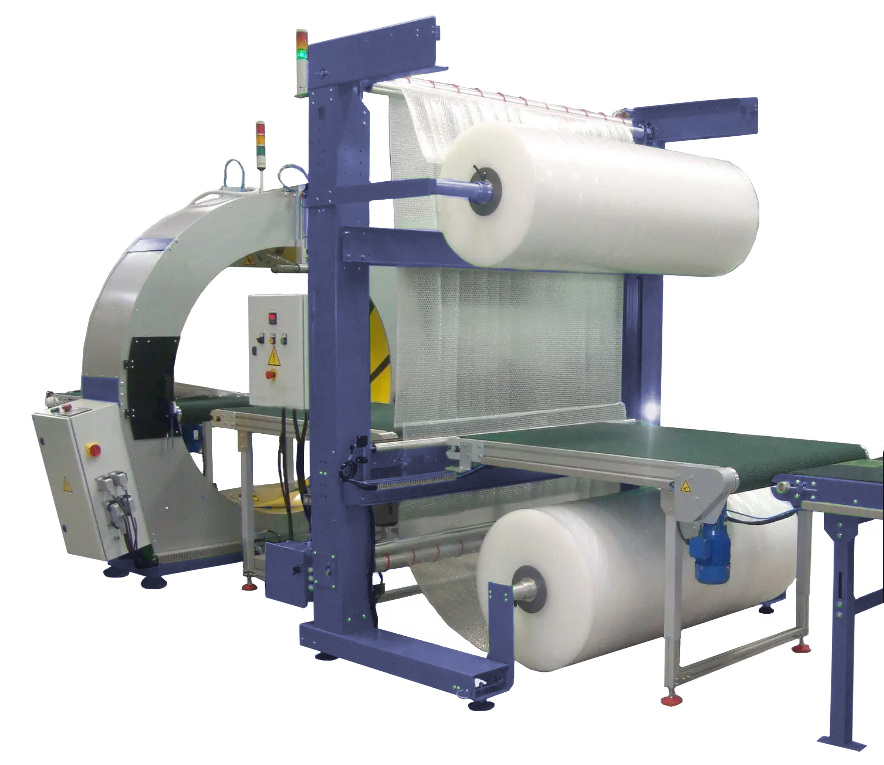

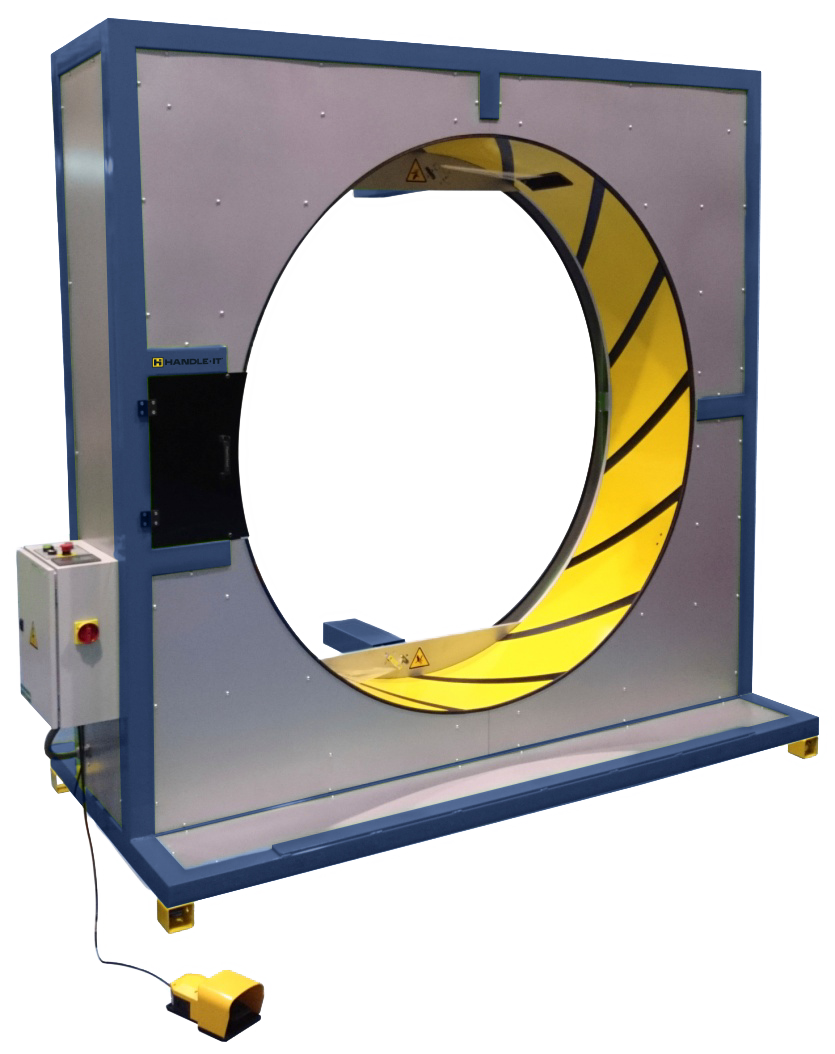

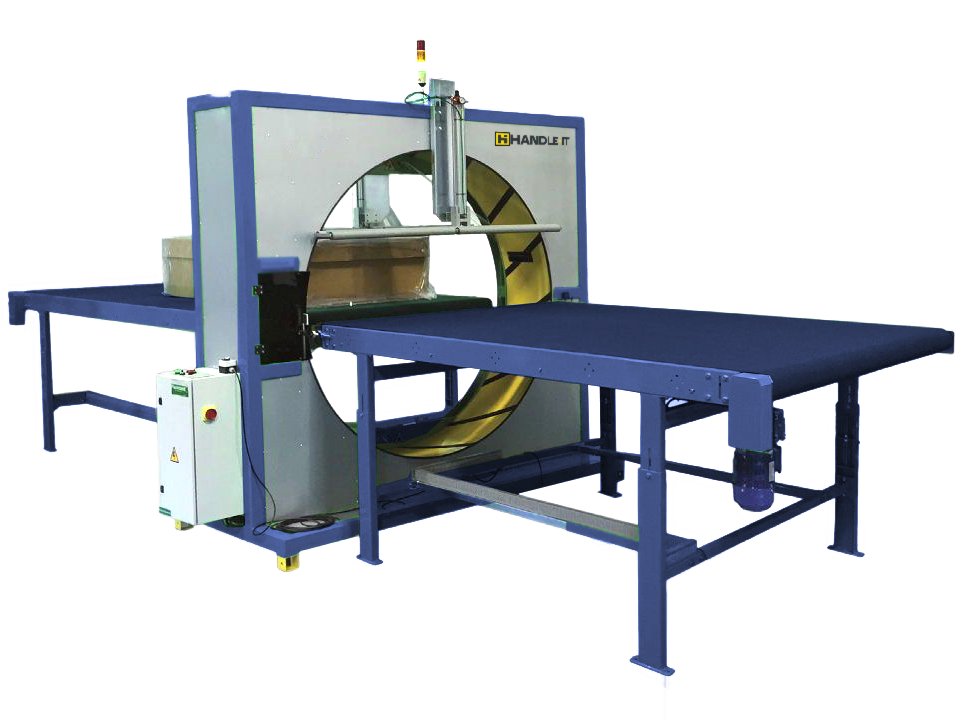

Double automatic dispenser for bubble wrap, foam, and polyethylene; compatible with Orbital Wrapper.

Applications:

Protection with bubble plastic, foam and polyethylene products like furniture, cabinets, doors, boards, modules, windows, delicate products.

Working process:

Through an infeed driven conveyor, the product automatically advances until the electrical photocell detects it, then the dispenser covers the product with bubble plastic · foam · polyethylene at the bottom, top as well as the front and back product sides. Upon reaching the wrapper ring, the product will be wrapped until the end of the process by covering the 6 product sides. Finally, the outfeed driven conveyor belt of the orbital wrapper pull out the product fully wrapped.

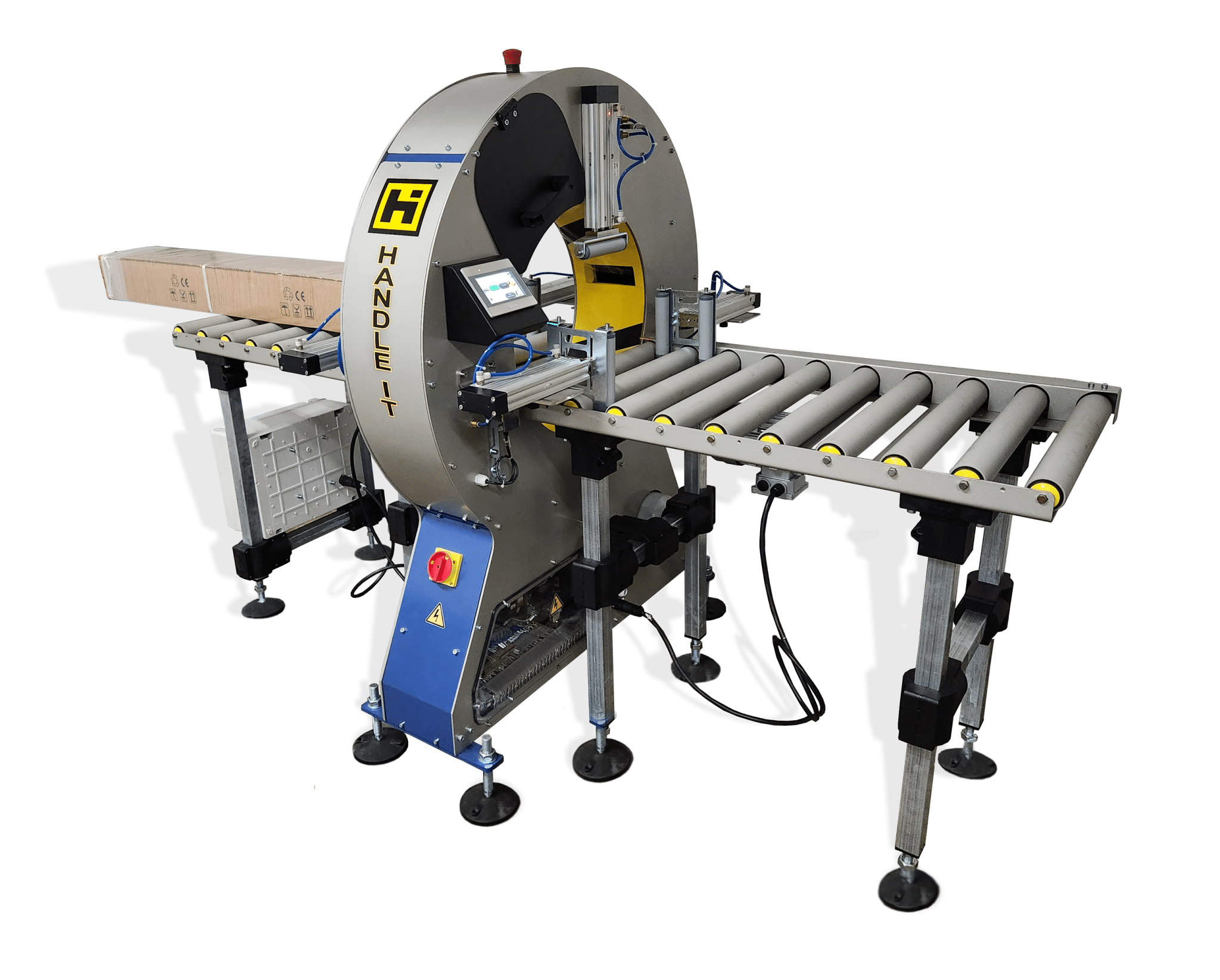

Standard Equipment:

- Welding head with double electrical resistance system for bubble plastic, foam and polyethylene.

- Double temperature regulator for electrical resistances.

- Automatic cutting system through blade for bubble plastic · foam · polyethylene.

- Side access door for easy coil change and threading.

- Device that unable the machine to work while changing the coil for user safety.

- Bottom and top coil holder available for bubble plastic and foam coils.

- Fast changing coils without shafts extraction nor tools.•Semiautomatic threading of bubble plastic · foam · polyethylene for coil change.

- Welding head transmission system through driven synchronized belts.

- Steel frame painted in gray and green, black base with scratch resistant paint.

- Interactive color touch screen, integrated on the side of the Bubble wrap Dispenser to program and adapt to the needs of the product to be wrapped:-Messages display.-Gifs explaining the activation of different functions.-Warning preventive maintenance-Available in 3 languages as standard.-Screen lock with password to avoid inappropriate manipulations of the chosen parameters.

- Electric photocell to start packaging cycle.

- Electric photocell to detect the product end to activate the welding head.

- Integrated electrical panel, incorporates master switch.

- Led warning light to inform status of HELIOS Dispenser (operative, working or emergency).